Table of Contents

EV Battery manufacturers produce electric vehicle batteries (EVBs), battery electric vehicles (BEVs), and hybrid electric vehicles (HEVs). The heart of an EV is the battery. Lithium has a very high energy density and can withstand charging and discharging well, so EVs mostly use lithium-ion batteries.

Despite potential alternatives like sodium-based batteries and solid-state batteries, lithium-ion batteries continue to dominate the energy storage technology landscape.

In the words of Elon Musk:

“In an electric future, batteries are as essential to transport as oil is today.”

Who makes batteries that keep EVs running? Keep reading to learn more about the world’s leading EV battery manufacturers.

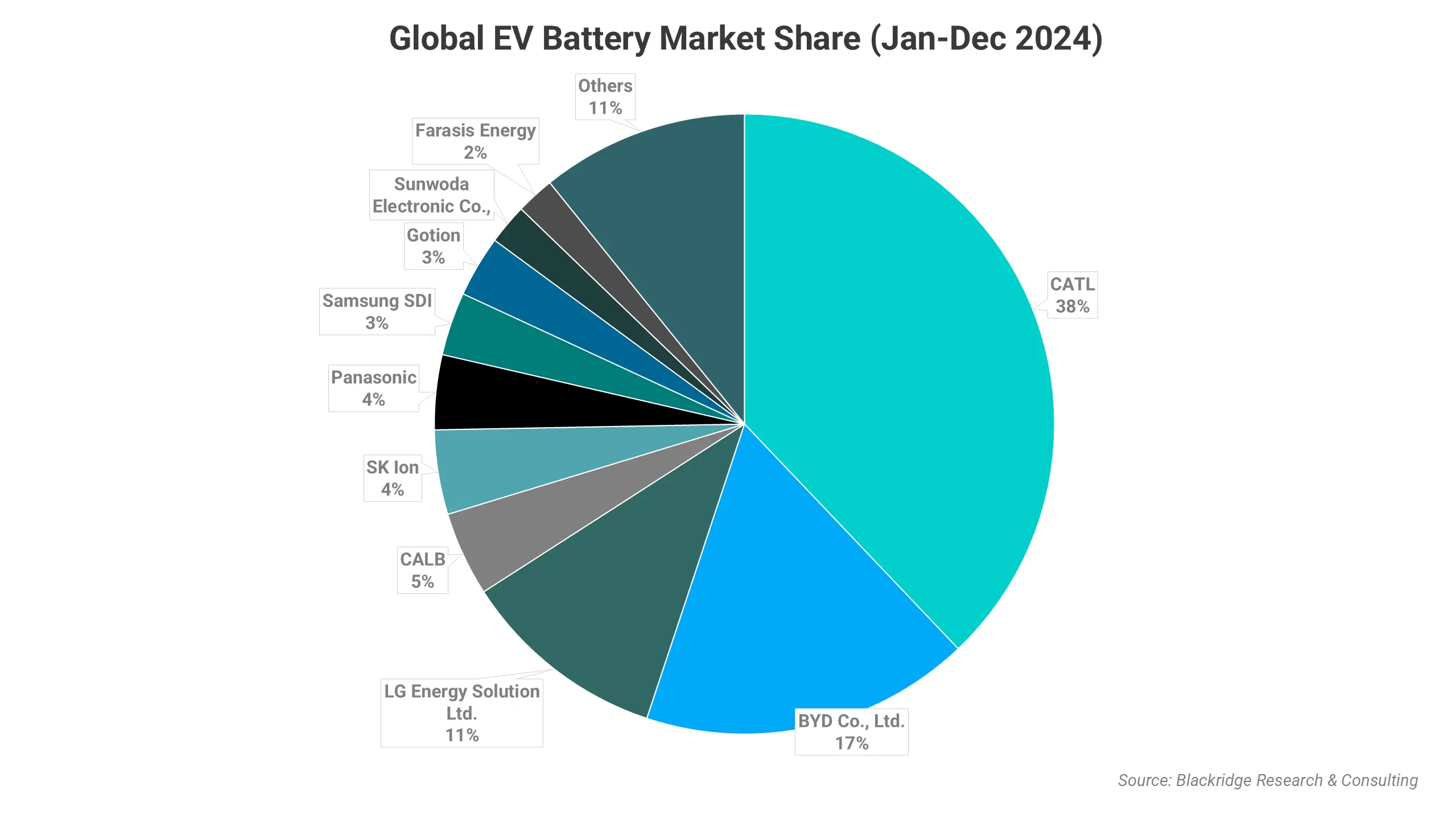

Global Top 10 EV Battery Manufacturers (2025) (ranked based on market share Jan-Dec 2024)

| Company | Founded | Location | Battery Types Produced | Market Share (Jan-Dec 2024) |

|---|---|---|---|---|

| CATL | 2011 | Ningde, Fujian, China | - LFP (Lithium Iron Phosphate) - NCM (Nickel Cobalt Manganese) - Sodium-ion - Qilin Battery (CTP 3.0) | 37.9% |

| BYD Co., Ltd. | 1995 | Shenzhen, Guangdong, China | - LFP (Lithium Iron Phosphate) - Blade Battery (LFP-based) | 17.2% |

| LG Energy Solution Ltd. | 2020 | Seoul, South Korea | - NCM (Nickel Cobalt Manganese) - NCA (Nickel Cobalt Aluminum) - LFP | 10.8% |

| CALB | 2009 | Luoyang, Henan, China | - LFP (Lithium Iron Phosphate) - NCM (Nickel Cobalt Manganese) | 4.4% |

| SK Innovation Co., Ltd. | 1962 | Seoul, South Korea | - NCM (Nickel Cobalt Manganese) | 4.4% |

| Panasonic Energy of North America | 1918 | Sparks, Nevada, United States | - NCA (Nickel Cobalt Aluminum) | 3.9% |

| Samsung SDI Co., Ltd. | 1970 | Yongin-si, South Korea | - NCM (Nickel Cobalt Manganese) - LFP | 3.3% |

| Gotion Power Energy | 2006 | Hefei, Anhui, China | - LFP (Lithium Iron Phosphate) - NCM (Nickel Cobalt Manganese) | 3.2% |

| Sunwoda Electronic Co., Ltd. | 1997 | Shenzhen, Guangdong, China | - LFP (Lithium Iron Phosphate) | 2.1% |

| Farasis Energy | 2002 | Hayward, California, United States | - NCM (Nickel-rich Lithium-ion) - Sodium-ion | 2.0% |

Here are the world’s leading EV battery manufacturers (based on the company’s market share in Jan-Dec 2024):

Contemporary Amperex Technology Co., Ltd. (CATL)

Contemporary Amperex Technology Co., Ltd. (CATL) is a Chinese manufacturer of lithium-ion batteries for EVs and ESS (Energy Storage Systems) and battery management systems.

According to the company, CATL has been “ranked No. 1 globally in EV battery consumption volume for five consecutive years.”

Headquartered in Ningde, Fujian, the company has 5 R&D centers and 13 production bases at various global locations.

CATL provides solutions for passenger vehicles, commercial applications, energy storage systems, and battery recycling.

CATL’s small and light high-power cells are tailored for hybrid EVs and provide key benefits, such as:

- High fuel-economizing rate (as high as 80%)

- Instant strong power

- Small body with high energy density

- Ultra-long service life

In addition, CATL’s electric private vehicle solutions are known for fast-charging technology, impressive system energy density, and ultra-long driving mileage.

Apart from launching its cutting-edge “Qilin” batteries in 2022, the world’s largest EV battery maker launched its EVOGO battery swap services in Hefei, Anhui.

On 2nd April 2025, CATL and Sinopec signed a strategic partnership to construct at least 500 battery swap stations within 2025 and expand to 10,000 stations in the long-term.

On 18th March 2025, CATL and Ellen MacArthur Foundation announced a strategic partnership under which a blueprint for battery circularity with entire battery value chain.

On 17th March 2025, CATL and NIO formed a strategic partnership to build world's largest battery swapping network. Under this agreement, CATL will support NIO in developing battery swapping network, whereas, Choco-Swap technical standards of CATL will be used in Firefly, NIO's new brand.

In the third quarter of 2024, CATL contributed to about 32.5% of the global EV battery shipments, shipping about 91.0 GWh of EV batteries. You can download a free sample to get complete insights about the Global Lithium-Ion Battery Market.

On 17 September 2024, CATL announced the ground-breaking TECTRANS battery system, which is revolutionizing the commercial transportation sector. It is designed to reduce downtime, improve cost-effectiveness, and improve overall efficiency.

On 12 February 2024, CATL, BYD, and Leading EV Manufacturers formed an alliance to advance the commercialization of solid-state batteries. In January 2024, the Chinese government formed the China All-Solid-State Battery Collaborative Innovation Platform (CASIP). The consortium was formed under this platform to enhance research and development in solid-state battery technology.

BYD Co., Ltd.

BYD Co., Ltd. (“BYD” is an abbreviation of “Build Your Dreams”) was founded by Chinese chemist Wang Chuanfu and is one of China’s largest privately owned enterprises with several subsidiaries.

Over the years, BYD has evolved into a leading technology company with more than 30 industrial parks across 6 continents and an industry leader in automotives, electronics, renewable energy, and rail transit.

As a globally leading producer of rechargeable batteries, including lithium-ion batteries, NCM batteries, and NiMH batteries, BYD owns the entire supply chain layout—from mineral battery cells to battery packs.

BYD’s batteries are ideal for a variety of uses, such as consumer electronics, energy storage, and new energy vehicles. The company launched the “Blade Battery” to mitigate battery safety concerns in electric vehicles like electric cars.

BYD’s Blade Battery successfully passed a nail penetration test. Moreover, its optimized battery pack structure increases the battery pack space by over 50%.

In addition, the robust chemistry and universal design of BYD’s cobalt-free LFP batteries (lithium iron phosphate batteries) make them suitable for use in a wide range of temperatures and areas worldwide.

On 3rd December 2024, BYD announced its partnership with TAILG a Chinese two-wheeler giant to develop two wheeler EV's like motorcycles, e-bikes and scooters.

BYD is the second largest battery manufacturer in China, In October it shipped about 15.82 GWh of batteries in EVs with a 26.7% market share.

LG Energy Solution Ltd.

LG Energy Solution Ltd. was founded in 2020 because LG Chem’s battery business officially became a separate company to address the growing demand from global automotive manufacturers.

The company has production bases in China, Korea, Poland, and the USA, with a business portfolio that includes:

- Advanced Automotive Battery (cells, modules, BMS, and pack products for EV batteries)

- Mobility & IT Battery (high-capacity, high-power, and ultra-slim batteries for IT devices and LEVs)

- ESS Battery (High-energy and high-output ESS battery products for power grids, UPS, and commercial and residential applications)

LG Energy Solution’s major fields of research include battery materials, lithium-ion cylindrical and polymer batteries, PEV (Plug-in Electric Vehicle) and PHEV batteries, and ESS batteries for grids and residential applications. With 30 years of R&D experience, the company has evolved into an ideal partner for global automakers to execute projects across the world.

On 1st April 2025, LG Energy Solution announced its US subsidiary will acquire General Motors (GM) stake in their joint EV battery plant in Lansing, Michigan for USD 2 billion. This acquisition is expected to close by 31st May 2025. This acquisition is driven my GM decision to exit EV battery manufacturing amidst recent US administration policies.

At Consumer Electronics Show 2025 (CES), LG Energy announced its partnership with Aptera Motors and CTNS to supply 4.4 GWh of advanced 2170 cylindrical battery cells for Aptera's EV vehicles form 2025-2031.

LG Energy Solution Ltd reported that it shipped about 29.0 GWh of EV batteries in the third quarter of 2024.

On 3rd December 2024, LG Energy Solution Ltd announced its plans to acquire General Motors Co's stake in their joint battery venture in the Lansing, Michigan plant. This includes the extension of their 14-year battery tech partnership to develop prismatic cell development.

On 2nd December 2024, LG Energy Solution Ltd announced its deal with General Motors to develop prismatic battery cells. Under this deal, both the companies will jointly manufacture prismatic battery cell technology and its related battery materials. These prismatic battery cells will power General Motors EV vehicles. This deal helps LGES to achieve a new milestone of becoming world's first battery manufacture to manufacture all three forms of battery - pouch type, cylindrica and prismatic cells.

On 4th April 2024, LG Energy Solutions announced its Battery Manufacturing Complex in Arizona is near to completion. On commission it will have a production capacity of 53 GWh with 36 GWh of cylindrical batteries and 17 GWh of LFP ESS batteries. Located in North America, it is the company's first stand-alone cylindrical and BESS battery plant in North America.

On 5th February 2024, LG Energy Solutions signed a deal with Hanwha Qcells. It is a USD 1 billion energy storage deal which is a milestone is the global ESS market. Under this agreement LG Energy will supply 4.8 GW of ESS batteries to Hanwha Q cells which will be installed in La Paz County, Arizona. The supply is expected to extend till October 2026.

Avail Discount on Customized Global Lithium-ion Battery Market Report Today! Download a Free Sample!

China Aviation Lithium Battery Co., Ltd. (CALB)

China Aviation Lithium Battery Co., Ltd. (CALB) is a global leader in new energy technology. CALB provides complete product solutions (cells and modules) and full life-cycle management for the following:

- Passenger vehicle market (includes a wide variety of electric vehicles)

- Commercial vehicle market (includes logistics vehicles, pure electric buses, slag trucks, and tractors)

- Energy storage market (includes prestigious projects like the State Grid Kunshan Energy Storage Power Station, which is the world’s largest grid-side lithium battery energy storage project)

- Special application market (includes airport service cars, electric forklifts, trackless rubber tire vehicles, and sightseeing boats)

Furthermore, the CALB simulation field supports the complete development process—from product conceptual design to delivery through the following simulations:

Safety reliability simulation (includes an assessment for battery capacity fade and Li-plating window analysis)

Electrochemistry simulation (includes cell performance evaluation and cell design optimization)

Structural mechanics simulation (includes structural strength analysis and swelling strength analysis)

Thermal management simulation (includes thermal distribution and propagation)

On 25th March 2025, CALB begin the construction of second phase of its Chengdu production base with an investment of CNY 12 billion (USD 1.67 billion). Once fully operational this plant will have a total capacity of 50 GWh. It is being built in two phases, the first phase has been completed in September 2022.

In February 2025, CALB announced its plans of constructing a Gigafactory in Portugal with EUR 2 billion. Initially, this plant is expected to have and annual capacity of 15 GWh in phase 1 with a potential to scale up in future. It is being planned in Sines, Portugal.

SK Innovation Co., Ltd.

SK Innovation Co., Ltd. is an energy and chemical company with eight subsidiaries, including SK on Co., Ltd., which has a successful track record of developing a high-energy density EV battery and mass-producing batteries like the NCM66 battery.

SK on’s business portfolio includes:

- Electric Vehicle Battery (provides various batteries depending on vehicle type through a global battery supply network)

The company uses high-nickel technology (nickel is a critical mineral of EV battery chemistry) and extensive manufacturing experience to supply batteries for EVs, HEVs, and PHEVs. Additionally, the local production process and supply network enable the collection of stable raw materials and an efficient supply of battery products.

- ESS (a full range of batteries, including cells, modules, racks, and optimized battery management systems)

- BaaS (Battery-as-a-Service includes services for the entire battery life-cycle)

In addition, SK on’s partnerships with key automobile OEMs and proprietary lithium extraction technology are furthering the company’s goal of building a BaaS ecosystem through battery rentals, recharging, reuse, and recycling.

On 21st March 2025, SK announced it will supply 100 GWh of US made batteries to Nissan under the supply agreement from 2028 to 2033.

On 19th March 2025, SK Innovation announced it has been awarded a supply agreement to supply EV batteries to Nissan Motor Co for its US operations. Under this agreement, SK will provide batteries for Nisaan's next gen EV's manufactured at Nissan's Canton, Mississippi plant. This agreement is set to commence in 2028 and will span 6 years.

Panasonic Energy of North America (PENA)

Founded in 1918 by Japanese industrialist Konosuke Matsushita, Panasonic Corporation (formerly known as “Matsushita Electric Industrial Co., Ltd.) is a globally recognized Japanese conglomerate with company operations organized into various “domain companies,” including appliances, automotive, and industrial solutions.

For instance, Panasonic Automotive is a leading Li-ion battery supplier in the global market for hybrid, plug-in hybrid, and full-electric vehicles with 40+ years of battery leadership.

The company also designs, engineers, and manufactures complete battery systems. It is known for its advanced lithium-ion battery technology that provides the benefits of lower costs, as well as improved energy density and driving range.

Furthermore, Panasonic Energy of North America (PENA) is one of the world’s largest lithium-ion battery cell producers with a vision of a clean energy society by producing the “world’s safest, highest quality, and lowest cost batteries.”

Apart from the company’s facility in Sparks, Nevada, a new facility in De Soto, Kansas, will produce cylindrical Li-ion batteries for electric vehicles to expand production capacity in North America and advance the EV industry in the U.S.

On 9th September 2024, Panasonic Energy announced the commencement of the mass production of 4680 cylindrical Automotive Lithium - ion Batteries in its Wakayama factory in Western Japan.

On 21st May 2024, Panasonic Energy announced groundbreaking to supply lithium-ion batteries for Tern, a zero-emission truck brand for its RC8 model.

On 29th February 2024, Panasonic Energy signed a deal with H&T Recharge a German battery component manufacturer. This collaboration began in 2017, under which H&T will supply 40 GWh of battery capacity annually to Panasonic Energy's Nevada facility.

Samsung SDI Co., Ltd.

Samsung SDI Co., Ltd. is a South Korean battery and electronic materials manufacturer with a global network of production, R&D, and sales and is credited with releasing the world’s first flexible (bendable and rollable) battery.

Since starting the lithium-ion rechargeable battery business in 2000, the company has consistently gained a significant market share in the small battery market.

Samsung SDI’s Li-ion battery cells are available in cylindrical, prismatic, and polymer types and provide various advantages, such as:

- Enhanced product quality and safety

- Higher energy efficiency

- Longer battery life

- Maximized ignition performance

- No emission during operation

- Smaller volume and weight

Samsung SDI makes small-sized Li-ion battery cells and battery packs for the following:

IT Devices

- Laptops

- Mobile phones

- Power banks

- Tablets

- Wearable devices

Power Devices

- Garden tools

- Power tools

- Vacuum cleaners

Trans Devices

- E-bikes

- E-scooters

- Ignition

On 2nd December 2024, The U.S. Energy Department announced its plans to assign a loan of up to USD 7.54 billion to the joint venture of Stellantis and Samsung SDI to build two electric vehicle lithium-ion battery plants in United States. This loan includes USD 6.85 billion as a principal amount and USD 688 million capitalized interest.

This venture will build 67 GWh batteries in Kokomo, Indiana, which will be used by electric vehicles for Stellantis. The 67 GWh batteries will be sufficient for 670,000 vehicles annually. Stellantis announced that the first electric vehicle lithium-ion battery plant will be open by 2025 and the second plant will be open by 2027.

On 3rd December 2023, Samsung SDI signed a deal with EcoPro BM. Under this deal, EcoPro BM will supply NCA (lithium nickel-cobalt-aluminium oxide) cathode Materials to Samsung SDI that will be used in manufacturing EV batteries for five years (2024-28). These cathode materials will be supplied to Samsung plants in South Korea and abroad.

Gotion High-tech Power Energy Co., Ltd.

Guoxuan High-tech Power Energy Co., Ltd. (also known as “Hefei Gotion Power Energy Co., Ltd.” and “Gotion High-Tech”) is a leading Chinese lithium-ion battery maker with a sizeable lithum-ion battery cell manufacturing footprint.

The company has a subsidiary in Fremont, California, United States, and various R&D centers worldwide. It also has an Industrial Technology Research Institute with comprehensive inspection and testing capabilities for batteries, battery systems, and power battery materials.

The company’s product portfolio includes:

- Battery management systems

- Energy storage batteries

- Lithium iron phosphate materials and batteries

- Power battery packs

- Ternary batteries

Gotion High-Tech provides battery products for the following:

- Passenger cars (iEV6EL accessory product battery pack and BAIC EC180 supporting product battery pack)

- Commercial vehicles (batteries suitable for electric buses)

- VIP cars (batteries for special vehicles)

- Low-speed cars (supporting products for low-speed vehicles)

- Energy storage cabinet (flexible and scalable three-level battery management system)

On 27th February 2025, Gotion and Toyota Tsusho Europe SA (TTESA), announced a partnership wherein, TTESA will handle the extensive sales network and project management and promote Gotion's BESS throughout European market.

Avail Discount on Customized Global Lithium-ion Battery Market Report Today! Download a Free Sample!

Sunwoda Electronic Co., Ltd.

Sunwoda Electronic Co., Ltd. (Sunwoda) is one of the industry leaders in the lithium-ion battery industry. Sunwoda’s business segments include 3C battery, energy service, EV battery, intelligent manufacturing and industrial internet, smart hardware, and testing service.

The company began its EV battery business in 2008. It owns several production bases across the world.

Sunwoda Electric Vehicle Battery Co., Ltd. is a wholly owned subsidiary of Sunwoda Electronic Co., Ltd. It provides EV battery pack solutions through advanced lithium battery integration technology and has complete R&D and manufacturing capabilities.

The company’s proprietary battery management system (BMS) is known for highly automated cell sorting, modular assembly, and battery packaging with entirely automated production lines.

Sunwoda’s EV battery solutions comprise the following:

Battery Cell

- BEV

- HEV

- PHEV (Plug-in Hybrid Electric Vechile)

BMS

- Centralized

- Distributed

Battery Module

- Block module

- Cylindrical module

- Soft package module

xEV Battery Pack

- Battery Pack

- 48V start-stop system

On 13th March 2025, Thailand's Board of Investment (BOI) approved a USD 1 billion investment by Sunwoda for EV and BESS manufacturing facilities in facilities in Thailand's Eastern Economic Corridor, Chonburi Province.

Farasis Energy

Starting with supplying battery systems to electric motorcycle customers, Farasis Energy expanded its battery business by entering the Chinese automotive industry in 2016 with large-scale battery delivery to Chinese OEMs.

In 2021, Farasis Energy started a lithium-ion cell manufacturing facility in Wuhu, Anhui province, with an annual production capacity of 24 GWh. The company’s battery products are available as “cells” and “modules” with tailor-made configurations for individual requirements.

Farasis Energy offers battery solutions for electric commercial and passenger vehicles and industrial machines.

Electric passenger vehicles (cars, motorcycles, aviation, and powersports)

Farasis Energy’s electric car batteries ensure fast charging, long range, and long life-cycle due to their high energy density and high performance.

The company is expanding its fourth-generation lithium-ion battery cells for EVs with an ultra-high-power variant that can achieve a fast charging time (less than 15 mins) while maintaining a high energy density (300 Wh/kg).

Electric commercial vehicles (buses and trucks)

The electrification of buses and trucks reduces air and noise pollution and makes cargo transport more environmentally friendly.

Farasis Energy’s battery systems for electric buses and trucks are known for their long life-cycle, safety and stability, and strong temperature adaptability.

In addition to established players in the EV battery market, other key companies include A123 systems, Envision AESC, PEVE, and SVOLT.

On 12th February 2025, Farasis Energy entered a partnership with Eberspächer, a leading automotive systems supplier. The partnership aims to deliver high-performance battery solutions ranging from 12 to 48 volts for backup and mild hybrid systems.

On 3rd October 2024, JMEV and Farasis Energy announced their cooperation agreement for the development of solid-state batteries. These batteries will be developed with the SPS (Super Pouch Solution) battery. This agreement will also include research, production and market application of the solid-state batteries.

EV Battery Market Trends and Forecast for 2025

The global EV battery market witnessness a spike in demand as prices continue to fall. In 2024, electric car sales rose by 25% to 17 million. The annual EV battery demand in 2024 surpassed 1 TWh (Terawatt-hour), says IEA (International Energy Agency) report.

EV Battery Prices in 2024-25

The EV battery prices have seen a dip in the year 2024, due to cheaper battery minerals. The widely used lithium iron battery has seen a dip in price by 85% compared to its peak price in 2022. This driver has led to investments in global battery manufacturing capacity which reached 3 TWh in 2024.

The Lithium-iron phosphate batteries (LFP batteries), due to its cheaper battery chemistry has been the most widely used and preferred EV battery over the globe. They are about 30% less expensive than other EV batteries such as lithium nickel cobalt manganese oxide (NMC) batteries.

The average price of a battery pack for EV car dropped below USD 100 per KWh (Kilowatt hour).

Top EV Battery Players in 2024

China continues to lead the battery market, as it produces over three quarters of batteries in 2024, the price of EV battery in China are reported to be cheaper than Europe and North America by over 30% and 20%. A decrease in EV battery prices has led to the rise in EV vehicles in China which are now cheaper than their conventional counterparts.

Over 70% of the EV batteries manufactured in China created a extensive manufacturing know-how. EV battery manufacturers like CATL, BYD have expanded their market share through innovation in EV battery sector. The decrease in EV batteries have also boosted the production which led to higher manufacturing yield compared to its competitors.

The big giants led supply chain integration as a result of acquisitions has led to decrease in manufacturing costs, boosting innovation and thus further strengthening the Chinese battery ecosystem. The Chinese battery ecosystem covers all the steps from mineral mining to refining, production and manufacturing of EV batteries.

As China continues to shine in the EV battery market, it is presenting challenges to the European market. In Europe the manufacturing costs are about 50% higher than China with relatively weaken battery ecosystem. Korea which is one of the largest EV battery manufacturer has also lost a major market share from 80% in 2022 to 60% in 2024.

EV Battery Market Outlook in 2025

China continues to expand its market share across Europe through integration and partnerships which includes its major move; the Stellantis one of the major EV car company and CATL formed a joint venture to capture the LFP batteries market share across Europe. While Korean Companies have started investing in making LFP batteries in Europe to regain the lost market share and compete with the Chinese manufacturers. These trends are expected to bridge the cost gap between Europe and China and likely further boost the global EV battery market. Looking for more such drivers and trends? Blackridge’s Global Electric Vehicle (EV) Battery Market is all you need!

Wrapping Up

EV battery manufacturing involves expertise and precision to produce safe, reliable batteries of different cell chemistries.

The rising demand for EVs and changing technology trends are encouraging battery makers to build state-of-the-art EV battery plants and boost EV battery manufacturing capacity.

Against the backdrop of tough competition between EV battery market players, the well-known automaker General Motors announced a huge investment to secure access to lithium—one of the essential battery materials for electric vehicles.

The strategic investment is part of GM’s effort to facilitate direct sourcing of critical EV raw materials and components, make the EV battery supply chain more secure, manage cell costs, and create jobs.

Toyota Motor is also catching up with competitors by planning to build a battery plant in North Carolina.

Additionally, Cirba Solutions will invest in a South Carolina battery recycling plant to process end-of-life hybrid and EV batteries, among others.

Furthermore, Saudi Arabia plans to build its first battery chemicals complex to process cathode active materials for the ever-growing EV battery market.

In the electric vehicle era, battery manufacturers are leveraging advanced battery technology to develop high-capacity, high-efficiency EV batteries and changing the energy paradigm of electric vehicles.

Are you looking for a comprehensive global EV battery market Report?

Blackridge Research & Consulting’s Global Electric Vehicle (EV) Battery Market report is all you need!

In this report, you will get insights about:

- Comprehensive market analysis

- Key industry players

- Evolving competitive landscape

- Emerging market trends and developments

- Expansion of global auto manufacturers into the EV market

- Increasing adoption of eco-friendly electric vehicles

- Financing and insurance options for EVs.

Contact us to learn more about the introductory offer and instant savings on your purchases.

![Global Top 10 EV Battery Manufacturers [2025]](https://images.blackridgeresearch.com/zA7C1E09-z4Uj64Eb0zfkw/e4072af5-2a62-4239-208c-5f531cacc000/public)

![Top 20 Lithium-ion Battery Manufacturers in India [2025]](https://images.blackridgeresearch.com/zA7C1E09-z4Uj64Eb0zfkw/df04849b-bdca-4c80-6431-2e007fa88300/public)

![Global Top 10 Battery Companies [2025]](https://images.blackridgeresearch.com/zA7C1E09-z4Uj64Eb0zfkw/f87c02e6-a954-44d8-3300-030fdd076500/public)

Leave a Comment

We love hearing from our readers and value your feedback. If you have any questions or comments about our content, feel free to leave a comment below.

We read every comment and do our best to respond to them all.