Table of Contents

Drill bit manufacturers manufacture a special tool that is used to make a hole in any solid material.

Generally, a drill bit typically contains the body, point, and shank, with the drill body extending from the shank to the outer corners of the cutting lips. While the shank refers to the part of a drill by which it is held and driven, the point is the cone-shaped cutting end of a drill.

Drill bits can drill through soft or hard materials and create different types of holes in diverse materials.

For example, a thick and sturdy masonry drill bit is used for drilling through concrete, but drilling clean, smooth cuts in wood is done with a wood drill bit.

While drilling creates a smooth hole in a material, tapping (using threaded tools called “taps”) creates an internal thread in a hole so that a bolt or screw can be inserted into the workpiece.

In the O&G industry, a drill bit (also known as a “bit” or a “rock bit”) is a cutting tool used to cut or crush rock. Based on the primary cutting mechanism, O&G drill bits are classified into two main types—fixed cutter bits and rolling cutter bits.

Drill bit companies specialize in developing drill bits that maximize ROP, provide a long service life, and are adaptable for several drilling applications.

Read on to learn more about the major players in the global drill bit market.

Global Top 10 Drill Bit Manufacturers [2025]

Here are the world’s leading drill bit manufacturers (listed alphabetically):

Atlas Copco

The Atlas Copco Group was founded as “Atlas” (1873), which became “Atlas Diesel” (1917) before being renamed “Atlas Copco” (1956).

Today, the 150-year-old company has customers in 180+ countries.

Atlas Copco supplies 19 mm, 22 mm, and 25 mm hexagonal rods in a variety of lengths and matching premium quality bits to meet diverse demands.

Atlas Copco’s product range covers Integral, Tapered, and R25 rods and bits applicable for the Atlas Copco Cobra Combi Breakers and Pneumatic Rock Drillers.

Here are the key features of Atlas Copco’s rods and bits:

- Excellent anti-corrosion and protection against breakage

- High wear resistance

- A longer service life

- Reduced risk of carbide failure

- Super-tough C253 premium quality steel specially designed for dry or wet drilling

Atlas Copco rotary drill bits

Atlas Copco rotary drill bits are available in open bearing and sealed bearing, as well as milled tooth or TCI bits. These rotary drill bits are designed to deliver high performance for water wells and oilfield drilling rigs.

Atlas Copco offers the following open bearing bits for the water well and work over market:

- Button bits (for water well, mining, and shallow drilling)

- Tooth bits (for well completion and workover)

Atlas Copco’s wide portfolio allows its customers to choose the best tool for each application—increasing productivity and reducing operation costs.

Atlas Copco on 26th February 2024, launched a drill for aerospace manufacturing, which is developed to improve quality and productivity on the aircraft assembly line. It is offered in two models, Standard and Plus for specific airframe tasks.

Also Read: Global Top 10 Hydraulic Fracturing Companies [2024]

Baker Hughes Company

Baker Hughes Company (Baker Hughes) is among the world’s largest oilfield service businesses, with operations spanning Africa, the Americas (including North America and South America), Asia-Pacific, Europe, and the Middle East.

Baker Hughes was established as a merger between Baker International (founded by Reuben C. Baker) and Hughes Tool Company (founded by Howard Hughes).

Baker Hughes is a trusted leader in solving production challenges in every environment—from deepwater subsea fields to mature conventional fields.

Baker Hughes’ drill bit solutions include:

Adaptive drill bits: Baker Hughes’ reliable adaptive drill bits autonomously adjust depth of cut to changing lithology, absorb shock, and help prevent damage to the bit and BHA (Bottom Hole Assembly).

These bits provide various advantages, such as extended tool life, optimized performance, as well as significantly reduced ILT (Invisible Lost Time) and NPT (Non-productive Time).

- TerrAdapt adaptive drill bit (mitigates stick-slip and reduces drilling costs)

PDC drill bits: Baker Hughes’ PDC (polycrystalline diamond compact) drill bits achieve maximum speed and efficiency while lowering drilling costs. Furthermore, the following shaped-cutter technologies optimize PDC bit performance in each application:

Shaped-cutter Technologies

StabilisX™ shaped-cutter technology prevents heavy impact damage by providing maximum durability for interbedded formations.

Shockwave™ shaped-cutter technology balances efficiency and durability and protects against thermal damage and chipping.

StayCool™ 2.0 shaped-cutter technology provides high cutting efficiency and wear resistance in hard, abrasive formations.

Apex™ shaped-cutter technology allows the cutter to penetrate ductile formations and maximize drilling rates.

Prism™ shaped-cutter technology delivers peak penetration rates in both ductile formations and hard, abrasive formations while maintaining durability.

PDC Drill Bits

- Dynamus extended-life drill bit (extends bit life and prevents damage that shortens the life of BHA)

- Talon Strike PDC drill bit (ensures consistent, cost-effective drilling performance)

Tricone drill bits: Baker Hughes’ tri-cone roller cone drill bits maximize performance while achieving a higher ROP (Rate of Penetration) with a lower cost per foot. Designed for the toughest drilling applications, the company’s product line includes:

- GX™ roller cone drill bits (ensure a higher ROP with fewer drilling hours and minimal NPT)

- Vanguard™ air performance tri cone drill bit (improves reliability and optimizes performance)

- Vanguard™ Arabia drill bit (increases bit life in carbonate drilling environments and provides exceptional ROP)

- Vanguard™ directional advanced tri-cone roller cone bit (decreases curve interval drilling time)

- Vanguard™ geothermal drill bit (increases tri cone drill bit life and improves drilling economics)

- Vanguard™ plug drill out bit (improves drilling efficiency in low WOB (Weight on Bit) applications

- Vanguard™ steel-tooth tri cone drill bit (increases ROP and mitigates bit balling with patented pyramid tooth-cutting structure)

Baker Hughes continues to engineer drill bit technology successfully through a multi-functional approach that uses proprietary engineering software to evaluate specific challenges and design custom solutions.

In 2024, Baker Hughes secured a contract with Petróleo Brasileiro S.A (Pertobas) for the construction services in the Buzios field offshore project in Brazil. The services contract will include drill bits, drilling services, wellbore clean up, cementing, fishing, remedial tools, fluids, services and geosciences. The contracted services is set start in first half of 2025.

Get a Customised Global Drill Bit Market Report Download a Sample Report!

Cangzhou Great Drill Bits Co., Ltd.

Cangzhou Great Drill Bits Co., Ltd. (also known as “Cangzhou Great” and stylized as “GREAT”) is one of the largest PDC bit manufacturers in Asia and is a first-class supplier for CNOOC, CNPC, and Sinopec.

Apart from selling products to Indonesia, the Middle East, Russia, the U.S. and other countries, GREAT is stated to have established strategic collaboration with all the oilfields in China.

The company specializes in the development, design, and production of drill bits and provides a wide range of products, including:

- Downhole Motor

- PDC Bit

- Matrix Body PDC Bit

- Steel Body PDC Bit

- Bi-Center Bit

- PDC Core Bit

- RC PDC Bit

- Hybrid Drill Bit

- Tricone Bit

- TCI Bit

- Steel Tooth Bit

- Roller Bit

- 90° U-shaped Roller Bit

- 120° U-shaped Roller Bit

- Starry Sky Roller Bit

- PDC Hole Opener

- Crocodile PDC Reamer

- Rock Reamer (for horizontal directional drilling projects)

- Roller Bit Core Barrel

- PDC Cutter

- Drag Bit

GREAT uses high-quality raw materials and a special processing technology to design different types of PDC bits. GREAT also provides 7/24 online service for drilling operations.

Here are the key advantages of using GREAT PDC bits:

- High ROP

- High-efficiency drilling

- More footage

- Reduced overall drilling costs

As one of the most professional drill bit manufacturers in China, GREAT controls the whole production process rigorously and inspects the finished drill bits and also makes several customized designs according to customers’ needs.

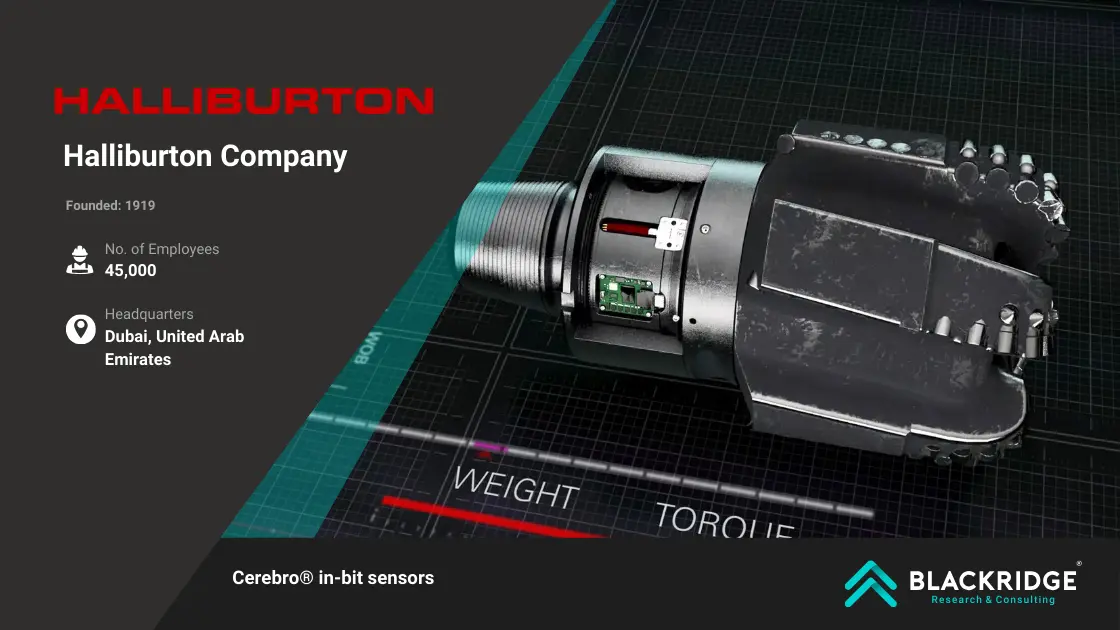

Halliburton Company

Halliburton Company (Halliburton) is a globally recognized provider of products, services, and integrated solutions for O&G exploration, development, and production. Halliburton was founded by Erle P. Halliburton—a pioneer in oil-well cementing.

Halliburton provides high-efficiency drill bits, coring, and hole enlargement tools for any drilling environment.

In addition to the unique Design at the Customer Interface (DatCISM) service platform that uses direct customer input to optimize drill bits, Halliburton’s Application Design Evaluation (ADE™) service specialists work with customers globally to provide application-specific solutions.

The Halliburton drill bits portfolio includes:

Fixed Cutter Drill Bits: Halliburton’s Hedron™ platform of fixed cutter drill bits combines an industry-leading customization process (DatCISM) with the proprietary iBitS™ modeling and simulation software (enabling 3D CAD (Computer-aided Design)/CAM (Computer-aided manufacturing)) to increase drilling performance and efficiency in the most challenging applications.

Furthermore, the following differentiate Hedron dill bits from the industry standard:

- Juggernaut™ cutter technology for increased abrasion and impact resistance

- Cerebro Force™ In-Bit Sensing for Downhole Data Insights

- Oculus™ Automated Dull Grading Analytics

Roller Cone Drill Bits: Halliburton’s StrikeForce™ roller cone drill bits are designed and developed to deliver improved cost per foot, performance, and reliability.

While dual high-performance seals reduce heat generation and seal friction, the contoured arms create directed flow channels. Additionally, these roller cone bits ensure fast ROP and increased bit revolutions (kRev).

Hybrid Drill Bits: Halliburton’s hybrid drill bits offer the perfect blend of fixed cutter and roller cone technologies for increased control, durability, and ROP without compromising stability.

The hybrid bit technology is engineered to withstand high WOB while reducing torque fluctuations for smoother drilling.

Halliburton’s Crush & Shear™ hybrid drill bits are engineered to provide extreme levels of strength and abrasion resistance and are ideally suited for the toughest of downhole drilling environments.

Also Read: Top 10 Largest Oil and Gas Companies| 2025 List

National Oilwell Varco, Inc. (NOV Inc.)

Formerly known as “National Oilwell Varco, Inc.,” NOV Inc. (NOV) is a world-renowned provider of oilfield equipment and technologies, including artificial lift solutions for O&G customers worldwide.

NOV Inc. is one of the top artificial lift companies in the world. It also provides oilfield services, supply chain integration services to the upstream O&G industry.

The NOV family of companies—NOV Completion & Production Solutions, NOV Rig Technologies, and NOV Wellbore Technologies—provides advanced equipment, operational support, and technical expertise necessary to optimize O&G drilling and production operations globally.

NOV’s comprehensive portfolio of drilling equipment and technologies includes:

- Automation

- Coiled Tubing Drilling

- Cuttings and Waste Management

- Data Acquisition

- Downhole Drilling Technologies

- Drilling Fluids

- Drilling Instrumentation

- Drilling Optimization

- Drilling Tubulars

- Fishing Tools

- Managed Pressure Drilling (MPD) Systems

- Pumps and Expendables

- Rig Equipment

- Solids Control

- Visualization, Reporting, and Analytics

- Workshop Equipment

Also Read: Global Top 10 Industrial Pump Manufacturers [2024]

NOV Drill Bits

Hercules Roller Cone Drill Bits provide a field-proven combination of durability, control, and speed for reliable and stable directional performance in interbedded and intrusive formations.

Pegasus Series Drill Bits with the patented dual-diameter design improve ROP and increase durability and stability even in the most challenging drilling environments.

Phoenix Series Drill Bits incorporate ION™ cutters with NOV’s patented deep-leach, thermal-stabilizing technology for abrasion resistance and increased toughness.

Tektonic Drill Bits feature advanced bit body geometry and the latest PDC cutter technology to deliver lower costs per foot, increase ROP, and minimize NPT.

Titan Large-Diameter Roller Cone Drill Bits with a rugged bearing design combined with a tough cutting structure are especially well suited to improve drilling rates and complete the interval in a single-bit run.

Rockpecker Limited

Rockpecker Limited (Rockpecker) is a globally leading designer and manufacturer of downhole drilling tools for directional drilling, geothermal, O&G, and water-well industries. Rockpecker’s global presence extends across Asia, Africa, Australia, Europe, New Zealand, and North America.

Rockpecker stocks all fast-moving configurations in its global stock centers and ships drilling bits and accessories worldwide within the quickest delivery time using the best logistics companies.

Rockpecker specializes in the design, production, and delivery of the following:

- PDC bits

- PDC hole openers

- Directional drilling equipment

- VRS (Versatile Replaceable System) hole openers

- Bolt-on VRS

- Weld-on VRS

- TCI (Tungsten Carbide Insert) drag bits for construction, geothermal, mining, and water-well applications

Rockpecker’s product range for the O&G industry comprises the following:

PDC drill bits: Rockpecker designs and manufactures steel and matrix body drill bits for directional and vertical applications.

Made in the UK, Rockpecker drill bits are built for the toughest drilling conditions with customer drilling objectives of reliable performance, repeatable quality, and low cost per foot in mind.

Hole openers

- PDC hole opener

- VRS hole opener with centralization

- VRS hole opener with hard-faced centralizer

- Staged PDC hole opener

- Bi-directional hole opener

Centralizers/Stabilizers

- 4 Blade

- 5 Blade

Rotary subs

- Pin to Pin

- Pin to Box

- Box to Box

As Rockpecker makes all its products in-house using high-grade materials, continuous product development methods, and precision engineering methods, it is able to respond to client modifications and requirements in short lead times.

Get a Customised Global Drill Bit Market Report Download a Sample Report!

Sandvik AB

Founded by Göran Fredrik Göransson, Sandvik AB is a Swedish engineering group specializing in mining and rock excavation, metal cutting, and materials technology.

Sandvik rotary drill bits

Sandvik rotary drill bits are suitable for diverse applications, such as construction, civil engineering, and mining. These rotary drill bits are available in air-cooled and sealed bearings, as well as a variety of carbide grades and insert geometries with cutting structures optimized for all conditions.

The Sandvik rotary drill bits range includes:

- Charger™ RR450 Rotary Bit

- Charger™ RR440 Rotary Bit

- RR340 Single Sealed Bearing Rotary Bit

- RR240 Air Bearing Rotary Bit

- RR910 & RR920 remedial service bits

Here are the key features of Sandvik rotary drill bits:

- A longer service life for reduced machine downtime

- Insert shapes and grades designed to provide high productivity

- Air-cooled bearing performance optimized for high hours

Sandvik’s design, manufacturing, and materials expertise ensure a product range capable of providing cost-effective, high-performance drilling for today’s challenging downhole conditions.

Schlumberger Ltd. (Schlumberger N.V.)

Schlumberger Ltd. (also known as “SLB”) is a globally renowned oilfield services company that is reported to be the “world’s largest offshore drilling company and offshore drilling contractor by revenue.”

Founded by Schlumberger brothers (Conrad Schlumberger and Marcel Schlumberger) as the Electric Prospecting Company, SLB has established itself as a company with a legacy worth celebrating and a pioneer unlocking new possibilities in energy access.

Schlumberger’s bit offerings include:

Blade family: The Blade family bits have been designed for maximum efficiency using elements with specialized 3D shapes to optimize performance well beyond conventional fixed and flat cutters.

With a history of record-breaking performance, Schlumberger blade bits have helped operators by delivering faster ROP, improving drilling efficiency, and reducing drilling costs.

- HyperBlade Hyperbolic Diamond Element Bit

- StingBlade Conical Diamond Element Bit

- StrataBlade Concave Diamond Element Bit

- AxeBlade Ridged Diamond Element Bit

- EnduroBlade 360 Rolling Diamond Element Bit

PDC bits: With the IDEAS (Integrated Dynamic Design and Analysis Platform) certification, Schlumberger PDC bits offer optimal performance and produce less torque and stick/slip in transitional drilling—greatly reducing the risk of time-consuming and costly trips due to shock and vibration.

As the IDEAS platform provides 4D simulations of the entire drillstring and wellbore geometry, it allows for material customization and real-time design. In addition, the dynamic modeling system helps predict bit and mill performance while eliminating expensive trial-and-error field tests.

- AccuStrike (short makeup drill bit)

- FireStorm PDC bits (wear-resistant, high-impact PDC cutter technology)

- Spear (shale-optimized, steel-body PDC drill bit)

- Aegis (3D-printed armor)

- SHARC (high-abrasion-resistance PDC drill bit)

Roller cone bits: Schlumberger’s customizable and reliable roller cone bits include TCI bits and MT (Milled Tooth) bits designed to withstand high temperatures and long run times while providing superior drilling performance through soft to ultrahard formations.

While the Xtra™ performance roller cone drill bit achieves high-performance drilling in any application, the Xplorer Helix configuration features a proprietary spiral layout that significantly improves ROP.

- Xplorer Premium Roller Cone Drill Bit

- Xtra Standard Roller Cone Drill Bit

Specialty bits: Schlumberger offers specialty bits for standard or rigorous applications. These bits provide premium performance, durability, and dynamic stability in demanding vertical and directional wells.

While Kinetic bits use application-specific materials to withstand the most rigorous drilling conditions, Impax hammer bits have diamond-enhanced inserts that increase the footage drilled and lower the cost per foot.

On the other hand, compact Quad-D bits with optimal gauge design enable quick directional response and enhance steerability.

- Kinetic Diamond-Impregnated Bit

- Quad-D Dual-Diameter Drift and Drill Bits

- Impax Diamond-Enhanced Insert (DEI) Hammer Bit

In addition to its high-quality product range, Schlumberger provides the following drilling optimization services:

- OptiWell (well construction performance service)

- OptiDrill (real-time drilling intelligence service)

- HFTO Suppressor Dampening Tool (absorbs and reduces high-frequency torsional vibration)

- Shock Sub (impact and vibration reduction tool)

- Engineered Drillstring Design (optimizes BHA for any application)

Also Read: Global Top 10 Carbon Capture Companies [2024]

Ulterra Drilling Technologies

Ulterra Drilling Technologies (Ulterra) is a globally leading provider of specialized drill bit solutions. According to an industry news source, Ulterra was acquired by Patterson-UTI Energy, a U.S. oil producer, in July 2023.

According to Ulterra, it is “the largest independent supplier of PDC drill bits for the O&G industry.” Furthermore, a Kimberlite Annual Research report (2022) states that “Ulterrra is the market leader of PDC bits in the U.S., with the best overall value and highest customer loyalty.”

Since 2005, Ulterra has enabled E&P operators to increase productivity, overcome performance limitations, and reduce costs with its high-quality drill bits and engineering services.

Ulterra continues to innovate with superior drilling technology and unique designs for challenging conditions while providing outstanding support across worldwide operations.

Ulterra’s PDC drill bit range includes:

Omega Cutters: Ulterra brings deep-leached cutter technology to the field in a fully fit-for-purpose drill bit with the combination of new product innovation and rapid iterative development.

CounterForce: Ulterra’s patented CounterForce technology combats drilling dysfunction caused by systemic lateral vibration and improves ROP while reducing costs.

Split Blade: Ulterra’s award-winning, high-performance Split Blade PDC bits save thousands of drilling hours through improved evacuation.

RipSaw: RipSaw’s active torque technology controls changing formations and increases reliability and stability in challenging drilling conditions.

WaveCut: WaveCut disrupts dysfunction and helps in drilling transitional and interbed formations faster and more efficiently while extending bit life for longer drilling intervals.

FastBack: FastBack combines superior materials for built-in toughness and maximum erosion resistance. Moreover, the tall, thin, sculpted blades of a FastBack are capable of reaching beyond traditional performance limits.

AirRaid: AirRaid is stated to be “the first and only PDC drill bit that offers the most in durability and toughness for air-drilling applications.” AirRaid is a revolutionary PDC bit solution that ensures minimal drilling time, low cuttings handling expenses, and reduced drilling fluid costs.

XP: Ulterra’s XP bits are specifically designed for each application and force balanced for maximum stability. While the over-engineered bit body ensures structural integrity, longer-lasting performance provides reliability even in the most demanding applications.

Hog: Ulterra’s HOG (Heavy Oil Gauge) PDC bits are designed to tackle the harsh conditions of the Canadian heavy oil sands. The HOG bits achieve high ROP while maintaining backreaming capability, durability, and steerability.

Varel International Energy Services, Inc. (Varel Energy Solutions)

Founded as “Varel Manufacturing,” Varel International Energy Services, Inc. (now known as “Varel Energy Solutions” or “Varel”) is one of the world’s largest independent manufacturers and suppliers of downhole drilling and completions products to the energy sector.

Varel’s high-impact PDC features are designed to optimize performance and value. Furthermore, Varel offers industry-leading steel teeth roller cone bits (workover bits) for re-entry and remedial operations.

Varel also provides integrated software solutions to develop the most optimized PDC drill bit design.

Varel drilling solutions include:

PDC Drill Bits

VION®: Created with a balanced cutting structure profile, the VION® PDC “Tangent” Drill Bit series is designed to overcome the ROP and durability challenges of drilling abrasive formations and transition zones.

EVOS™: The EVOS PDC Directional “Build” Drill Bit series ensures optimal ROP with maximized tool face control for any well program and lithology challenges.

HAVOX™: The HAVOX PDC “Hold” Drill Bit series provides advanced directional control, dynamic stability, excellent well bore quality, and smooth torque for any directional wellbore application.

COREBIT: VAREL COREBIT is designed for soft-to-hard formation coring and is customizable to the core barrel required, making every COREBIT application unique.

FUSION®: Designed for all high-speed motor and turbine applications, the high-performance FUSION® bits deliver optimal drilling performance in very challenging formations.

BI-CENTER: BI-CENTER is designed to enlarge the wellbore by 15% to 25% larger than the pass-through wellbore in all types of formations. BI-CENTER is ideal for rotary, directional motor, and Point-the-Bit RSS (Rotary Steerable System) applications.

Roller Cone Drill Bits

SLIPSTREAM®: SLIPSTREAM® bits are ideal for all motor and rotary applications. Designed to target non-homogeneous downhole components, these bits have tungsten carbide inserts and hard-faced steel teeth arrayed in the cutting structure to cut hard and soft materials found in frac plugs.

SLIPXTREME®: SLIPXTREME® is based on the latest generation of hybrid cutting technology designed for milling. The solution drill bit is engineered to tackle variable downhole components like bridge and frac plugs, as well as the more demanding requirements of cast iron or ceramic slips.

EVEREST: EVEREST is a roller bearing product line designed for large diameter drilling and known for consistent performance and reliability in surface and intermediate hole sections.

HIGH ENERGY: Available in both steel teeth and tungsten carbide insert drill bits, HIGH ENERGY drill bits come with application-specific features and patented bearing components, which make them ideal for directional drilling as well as straight hole applications.

COMPASS: The COMPASS product provides reliable performance in diverse applications, including coiled tubing operations, reduced casing programs, re-entries, and laterals.

A-FORCE: A-FORCE is a dedicated product line for drilling with air, water mist, and/or foam fluid systems in all under-balanced applications.

Wrapping Up

Drill bits are available in different coating materials, dimensions, shapes, and sizes for a wide range of applications—from construction and mining to petroleum exploration and woodworking.

For instance, titanium aluminum nitride is a high-performance coating that enables greater feeds and speeds and also reduces friction to extend tool life.

When it comes to cutting tool materials, high-speed steel (HSS) is widely used in drill bits and power-saw blades, with HSS being typically harder than stainless steel.

In addition, HSS drill bits are more durable and long-lasting than carbon steel drill bits used for cutting materials like hardwood and soft metals.

In a related context, a step drill bit is a single conical-shaped bit that allows drilling holes of multiple sizes with the same drill bit.

While a carbide drill works well for drilling holes, carbide rotary burrs are used for cutting, grinding, shaping, and the removal of excess material or sharp edges.

On the other hand, solid carbide drill bits are ideal for high-production drilling but are not suitable for hand tools like cordless drills.

Depending on the drilling method and the type of rock formation being drilled, different rock drill bit sizes are also used for drilling applications.

For example, small-diameter top hammer button bits are commonly used for drilling anchor holes and shallow blast holes but large-diameter top hammer button bits are used for drilling large blast holes in hard rock formations.

In the O&G industry, drill bit innovation addresses the increasing complexity and scope of drilling applications with continuously evolving drill bits designed to enhance drilling efficiency—enabling drillers and operators to drill better, faster, and at lower cost.

Drill bit manufacturers not only manufacture a comprehensive range of cutting-edge drill bits and related products but also provide drilling optimization services to support O&G operations worldwide.

Are you Looking for a Comprehensive Global Drill Bit Market Report?

Blackridge Research & Consulting’s Global Drill Bit Market Report is all you need!

In this report, you will get insights about:

- Competitive landscape

- Emerging market trends

- Market challenges and opportunities

- Market shares of key players

- The most influential growth drivers and restraints

Contact us to learn more about the introductory offer and instant savings on your purchases.

![Global Top 10 Drill Bit Manufacturers [2025]](https://images.blackridgeresearch.com/zA7C1E09-z4Uj64Eb0zfkw/66d1a45a-faea-468f-7d5d-ec6e18d64100/public)

Leave a Comment

We love hearing from our readers and value your feedback. If you have any questions or comments about our content, feel free to leave a comment below.

We read every comment and do our best to respond to them all.