Table of Contents

Category | Details |

Project Name | Triton FPSO |

Country | United Kingdom |

Operator | Dana Petroleum Limited |

Oil Field | Triton Oil And Gas Fields |

Location | UK Central North Sea, Block 21/30, approximately 193 km (120 miles) east of Aberdeen |

Storage Capacity | 630,000 barrels |

Processing Capacity | |

* Oil | 105,000 bopd |

* Gas | 140 mmcfd |

*Water Injection | 125,000 b/d |

Vessel Status | Active |

Total Project Cost | USD 338 Million (1997) |

Ownership | Dana Petroleum (52%) Tailwind Mistral (46%) Waldorf Production UK plc (2%) |

Oil Production Started Year | 2000 |

Crew Capacity | Approximately 70 |

Overview

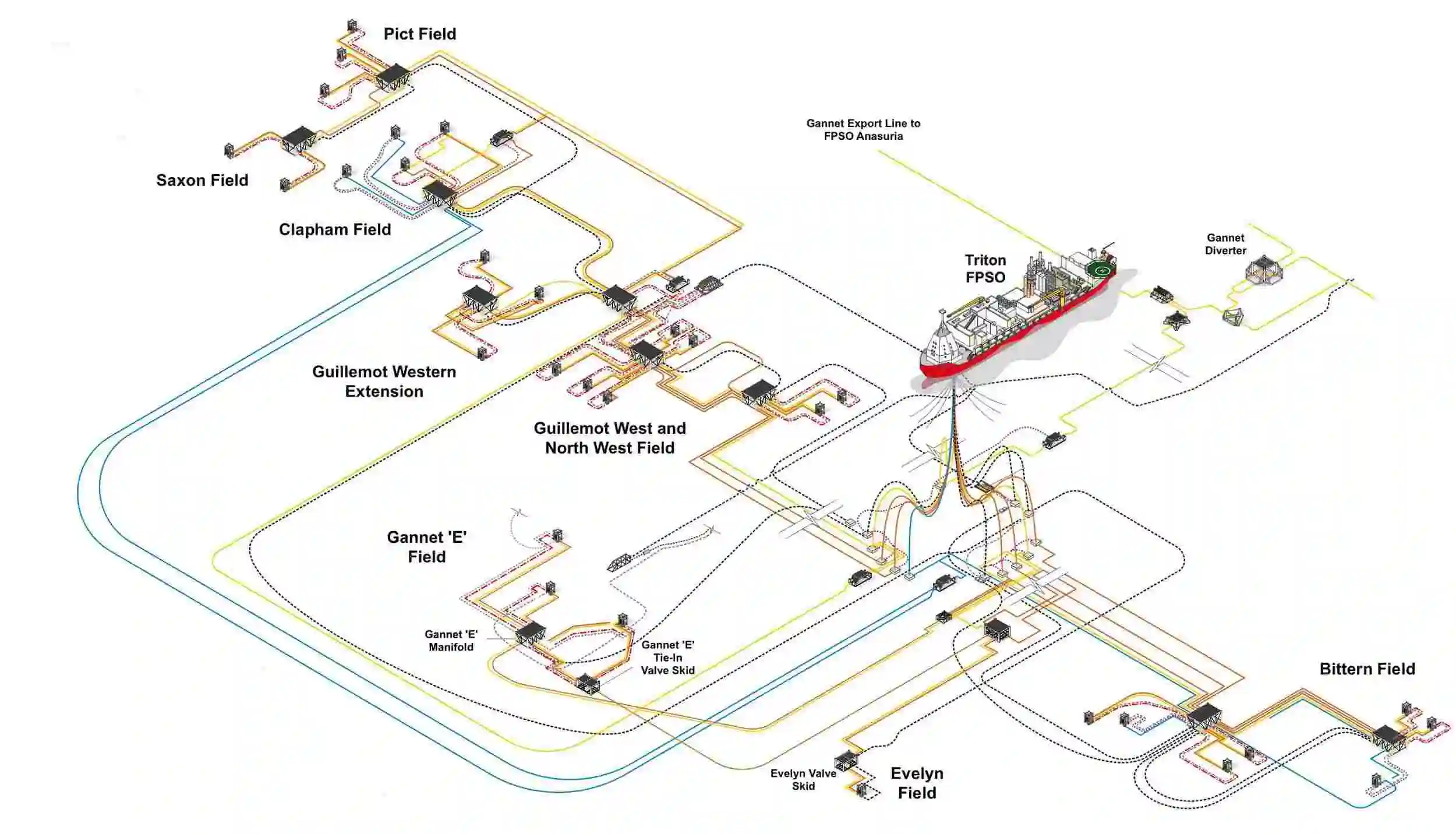

The Triton FPSO (Floating Production Storage and Offloading) unit, operated by Dana Petroleum Plc, is in the UK North Sea, located in Block 21/30, approximately 193 km east of Aberdeen. This FPSO began its oil production in 2000, serving as a crucial hub for processing and storing hydrocarbons extracted from multiple fields, including Bittern, Guillemot North West fields, Gannet E, Clapham, Pict, and Saxon.

The FPSO has a notable storage capacity of 630,000 barrels and impressive processing capabilities—105,000 barrels of oil per day (bopd), 140 million cubic feet of gas per day (mmcfd), and 125,000 barrels per day (b/d) of water injection. The vessel is designed to accommodate approximately 70 crew members, ensuring efficient and continuous operation. The total project cost for the Triton FPSO was around USD 338 million in 1997.

The floating offshore production vessel is well-integrated into subsea development involving pipelines and manifolds tied to the FPSO. Oil is exported via shuttle tankers, while gas is transported through the Fulmar gas line to St Fergus. The ownership structure comprises Dana Petroleum Limited holding a 52% stake, Tailwind Mistral (serica energy) at 46%, and Waldorf Production UK plc at 2%. The FPSO remains active, with drilling conducted by mobile units over the respective fields and pipeline intervention and inspection carried out by DSV and ROV inspection vessels, ensuring the operational integrity and safety of the subsea facilities.

40+ reviews

Find the Latest FPSO & FSO (Oil & Gas) Projects in United Kingdom (UK) with Ease

Gain exclusive access to our industry-leading database of FPSO project opportunities with detailed timelines and stakeholder information.

Collect Your Free Leads Here!

No credit cardUp-to-date coverage

Joined by 750+ industry professionals last month

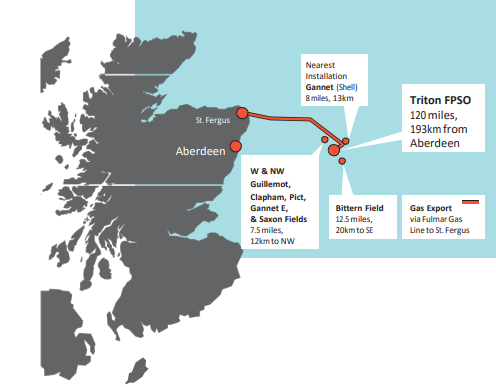

FPSO Triton location

The Triton FPSO is located in Block 21/30 of the UK Central North Sea, approximately 120 miles (193 kilometers) east of Aberdeen.

Project Background

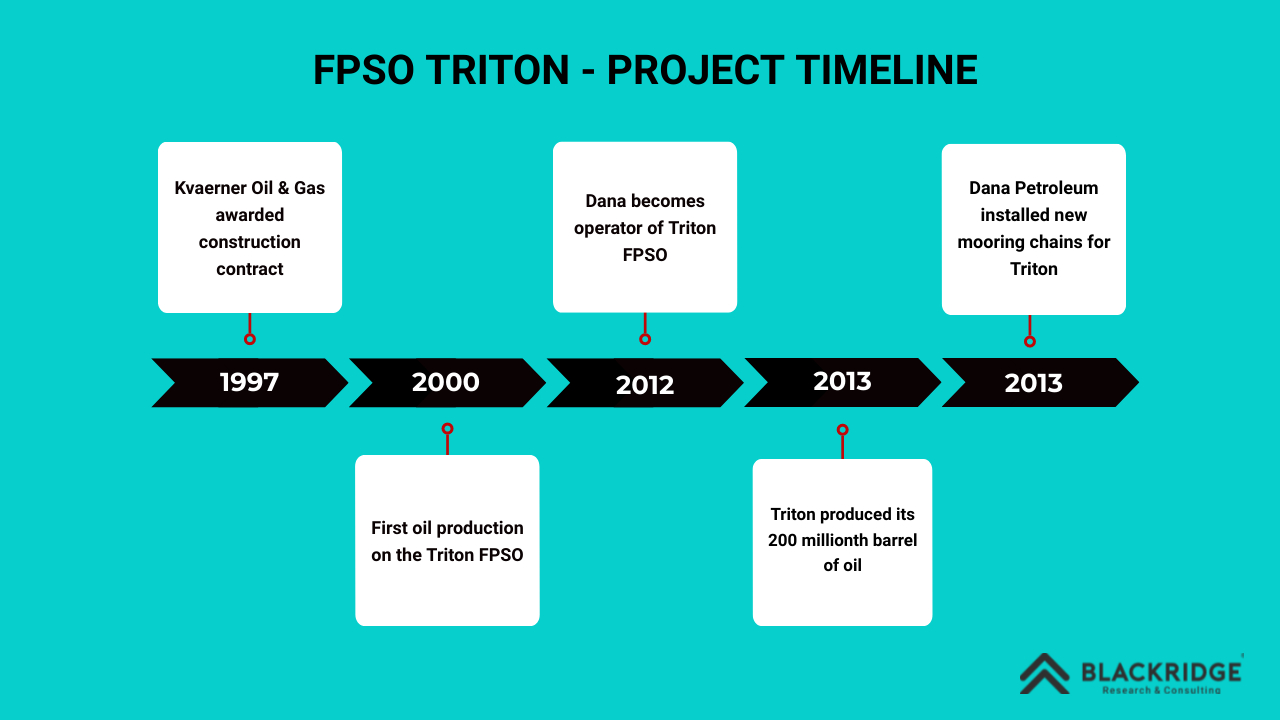

The Triton FPSO project began with a USD 338 million contract awarded to Kværner by Amerada Hess on August 28, 1997, for its design and construction. The project's foundation was a 224-meter-long, 105,000-deadweight-ton (dwt) Aframax double-hulled tanker, initially under construction at Samsung Heavy Industries in South Korea. This tanker was acquired and transformed into a production vessel.

The conversion work involved moving the hull to the Sembawang yard in Singapore, where extensive strengthening around the moonpool and turret area, as well as the installation of the moonpool casing, was carried out between August and November 1998. Subsequently, the vessel sailed to the Tees Offshore Base in the UK and arrived on December 6, where its engines were removed and mothballed.

At Tees, Kværner's workforce from the Port Clarence fabrication facility installed and commissioned approximately 7,500 tons of process and utility equipment, assembling the process topsides. The vessel features an internal bow turret mooring system designed by Bluewater, with a 4.4-meter diameter and three by three lines, each 1250 meters long, fabricated by Lewis Offshore. The vessel was towed to its field location in block 21/30 by Stolt Comex Seaway in the autumn, positioned 20 km northwest of Bittern and 10 km southeast of the Guillemot area.

Designed to handle 105,000 bopd (oil equivalent), 140 million cubic feet per day of gas, and inject 125,000 barrels of water, the FPSO has a storage capacity of 630,000 barrels of oil. Offshore oil loading is conducted from the stern, while gas is exported via a 10-inch, 12 km spur line to the Fulmar gas trunk line. The subsea facilities contract was awarded to Stolt Comex Seaway, with significant subcontracts for pipeline and system design, manifolds, and seabed umbilicals.

The project faced challenges such as long tieback distances and the need to prevent wax deposition in the pipelines, which were addressed through pipe-in-pipe insulation and permanent pigging facilities. The first oil production was in 2000; in 2012, Dana Petroleum Ep Limited became the operator.

Design and Engineering Details

The Triton FPSO was constructed as a new-build double-hull tanker in Korea and later modified at the Sembawang shipyard in Singapore. The vessel, which measures 244 meters in length, 42 meters in breadth, and 21.3 meters in depth, has a deadweight of 105,000 tonnes. It features a passive mooring system designed by Bluewater, utilizing a 4.4-meter diameter internal bow turret with 3 x 3 mooring lines, each 1,250 meters long, in a chain/wire/chain configuration.

The riser system comprises nine flexible risers and four umbilicals, with 15 riser slots for future additions. Topsides, cranes, and other equipment were installed and commissioned at the Tees Offshore Base in the UK. Operating in a water depth of 300 feet (90 meters), the vessel generates 42 MW of power from two LM6000 dual-fuelled gas turbines.

Project Timeline

Project Cost

Project Cost

On August 28, 1997, Amerada awarded Kværner a USD 338 million contract for the design and construction of the Triton FPSO.

Contractors Involved

Contractor | Role | Description |

Dana Petroleum | Operator | Overall Management & Operations, Enhancement Projects (Mooring Chains, Well Tie-Backs) |

Kvaerner | Overall Construction | Awarded Construction Contract (Project Initiation) |

Tailwind Energy | Equity Partner | Bittern Field and Other Fields, Collaboration on New Wells & Production Tie-Ins |

TechnipFMC | Subsea Contractor | Project Management, Engineering, Flexible Risers & Subsea Infrastructure Installation |

Petrofac & Stena Drilling | Well Completion | Drilling & Completion of New Wells (e.g., B5 Well) |

InterMoor, Subsea 7, Wood Group PSN, Optimus | Mooring Replacement | Replacement of Mooring Chains (using Vicinay Chains & Specialist Vessels) |

Shell UK & Esso Exploration and Production UK | Joint Venture Partners | Equity Stake in Triton FPSO Project |

Samsung Heavy Industries | Hull Construction | Construction of Original Hull for FPSO Conversion |

Sembawang Shipyard | Modification | Modifications to Converted FPSO Hull |

Bluewater | Internal Turret Design | Design of Internal Bow Turret Mooring System |

Emerson | Control Systems | N/A |

Environment Compliances

The Triton FPSO adheres to stringent environmental compliance measures, featuring a double-hulled design and processes aimed at minimizing VOC emissions. It employs high-efficiency turbines and waste heat recovery systems to enhance energy efficiency and reduce exhaust gas emissions. In the event of a spill, initial response and monitoring are managed by the FPSO management and Dana Petroleum, with escalation to field operators if additional external resources are required.

Procedures are in place to minimize discharges, and comprehensive oil pollution emergency plans are prepared to handle significant incidents, considering factors such as weather, spill amount, location, and local sensitivities. Additionally, as a member of Oil Spill Response, the Triton FPSO has access to extensive expertise, equipment, and dispersants to manage spill incidents effectively.

Current and Future Prospects

Since 2012, Dana Petroleum has operated the Triton FPSO, which is nearing the end of its design life. The company faces the challenge of ensuring the vessel can continue production until 2030 while meeting regulatory requirements and Triton Performance Standards. To address this, Dana Petroleum must develop a comprehensive maintenance plan to keep the FPSO Triton on-station and producing efficiently, extending its operational life and ensuring ongoing compliance with industry standards and regulations. This includes developing development potential projects like the Belinda Field, which is expected to see production tied back to the Triton FPSO in 2026.

Recent Update: Serica Energy has confirmed that production from the Triton FPSO, operated by Dana Petroleum, has resumed following a temporary shutdown in late September due to a flare system issue. Output has now been ramped up to over 25,000 boepd net to Serica.

Additional Information

The standby Ocean Osprey, shared with the Gannet and Anasuria assets, supports the Triton FPSO. Owned and operated by Atlantic Offshore, this emergency rescue, recovery, and tanker assist vessel was built in 2014. It measures 66.80 meters in length and 16.00 meters in breadth, powered by 2 x 1935 kW MAN engines, with a speed of 14 knots.

The Ocean Osprey has a WEEDO 800 fast rescue craft, two MP 1000 daughter crafts, and three heave-compensated launching systems. It features rescue zones with port and starboard and a Dacon Scoop Recovery System. It fully complies with Class A SBV requirements and can accommodate 400 survivors with seating, bunks, a hospital treatment area, showers, and toilets.

The vessel operates 8 miles (13 km) west and northwest of Triton FPSO, 120 miles (193 km) from Aberdeen. Gas is exported from the FPSO via the Fulmar Gas Line to St. Fergus.

Conclusion

The Triton FPSO, operated by Dana Petroleum in the Triton area, has been a vital asset for offshore industry since its inception in 2000. With substantial storage and processing capacities, it plays a crucial role in hydrocarbon extraction from various fields. Despite nearing the end of its design life, Dana Petroleum is actively managing its maintenance to ensure continued operation until 2030, demonstrating a commitment to both efficiency and regulatory compliance. Supported by robust environmental measures and strategic partnerships, the Triton FPSO remains a cornerstone of offshore production in the region.

Connect with decision-makers of FPSO projects in the UK for business opportunities.

Subscribe to our UK FPSO Project and Tender Database to access reliable and high-quality insights on upcoming, in-progress, and completed FPSO projects across the world or in your desired location.

Our user-friendly platform provides essential details, timely updates, key stakeholder contact information, and business opportunities tailored for engineering companies, industry professionals, investors, and government agencies.

Start a free demo to take your business to the next level!

Leave a Comment

We love hearing from our readers and value your feedback. If you have any questions or comments about our content, feel free to leave a comment below.

We read every comment and do our best to respond to them all.