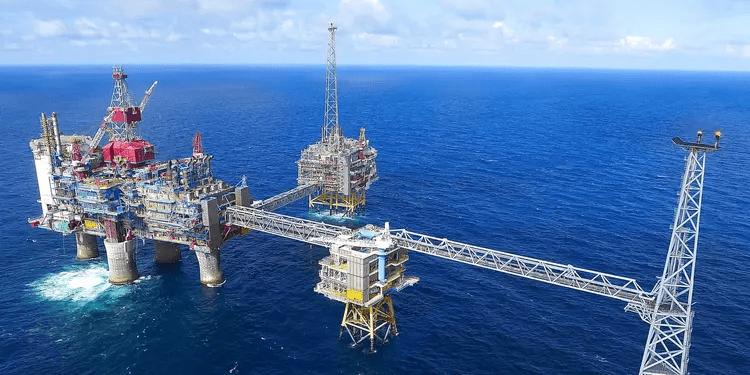

Shell Contracts Cleanova for Filtration Systems on Brazil's Deepwater Gato do Mato FPSO

Shell has contracted Cleanova to supply filtration systems for the new Gato do Mato FPSO, which will be installed in 2,000 meters of water, approximately 200 kilometers south of Rio de Janeiro. The equipment will remove sulfate from seawater prior to injection into the Gato do Mato Field reservoirs and eliminate solid contaminants dislodged during cleaning operations.

FPSO Production Specifications

The Gato do Mato FPSO will have the capacity to produce up to 120,000 barrels per day of oil and up to 384 million cubic feet per day of gas. The floating production unit will feature crude storage capacity for 850,000 barrels.

40+ reviews

Find the Latest FPSO & FSO (Oil & Gas) Projects in Brazil

Gain exclusive access to our industry-leading database of offshore wind opportunities with detailed project timelines and stakeholder information.

Collect Your Free Leads Here!

No credit cardUp-to-date coverage

Joined by 750+ industry professionals last month

Filtration Technology and Equipment Details

Cleanova will supply sulfate removal units (SRU) and cleaning-in-place (CIP) filters based on its proprietary filtration technology. Each filtration system will be capable of removing high volumes of solid contaminants ranging from one to 90 microns to β5000 efficiency levels, with minimal impact on process parameters. The polypropylene filter elements in these systems are only five microns thick, which is roughly 20 times thinner than a human hair.

Macer Braidwood, Cleanova's global market manager, stated that the filters are “designed for heavy dirt loads, meaning fewer filter changes, while offering extremely fine filtration for maximum particulate capture.” Each of Cleanova's HC filter cartridges features a layered and pleated media structure optimized to maximize particle capture over a wide range of particulate sizes. The outside-to-inside flow design, coupled with the O-Ring seal, provides effective removal of contaminants and a higher dirt-holding capacity.

System Functions and Operational Benefits

The SRU system will remove sulfates from seawater prior to injection into the oil reservoir, helping to safeguard against scale formation and souring. The CIP unit will filter out particulates and residue dislodged during cleaning operations, preventing contaminants from reentering the system. Cleanova states that its filtration systems will maintain product quality and operational efficiency through preventing contamination and damage to equipment. The company expects to deliver the SRU and CIP filter systems in July of next year.

Connect with Decision-makers about the Latest FPSO & FSO (Oil & Gas) Projects in Brazil for business Opportunities.

Subscribe to our database on FPSO & FSO (Oil & Gas) Projects and Tenders in Brazil to get access to reliable and high-quality insights on upcoming, under-construction, and completed FPSO & FSO (Oil & Gas) Projects across the world or in your desired geographical location.

Our user-friendly platform provides essential details, timely updates, key stakeholder contact information, and business opportunities tailored for engineering companies, industry professionals, investors, and government agencies.

Leave a Comment

We love hearing from our readers and value your feedback. If you have any questions or comments about our content, feel free to leave a comment below.

We read every comment and do our best to respond to them all.