Find the Latest Chemical Manufacturing Plant Projects in Malaysia with Ease.

Discovering and tracking projects and tenders is not easy. With Blackridge Research's Global Project Tracking (GPT) platform, you can identify the right opportunities and grow your pipeline while saving precious time and money doing it.

- Free! No Strings Attached

- Personalized

- 15 to 20 minutes

Trusted by Industry Leading Companies

See projects in other countries

Stages Covered

Upcoming

Announced, Study, Planning, and Design/FEED stage Projects.

Tenders

Pre-qualification, Main Contract Bid, and Bid Evaluation Projects.

Contract Awards

Recent Project Awards

Under-construction

Projects currently in pre-construction and under-construction.

Completed

Projects that have been successfully completed and are operational.

Find upcoming projects and tenders in Malaysia with ease

Key Contact Details

Build a conversation with decision makers and get ahead of competitors early on

Email Alerts

Stay up to-date and get important updates with customizable email alerts

Best in Industry Support

Get expert support and quick resolution of issues with our always available email, phone, and chat-based assistance

Easy-to-use Interface

Clean and user friendly interface to quickly and easily find what you re looking for

Real-time Access to Continually Updated Data

Quickly act on new opportunities and make informed decisions.

High Quality & Reliable Data

Accurate data enhances efficiency and enables to make informed decisions

As featured on

The best choice for your needs

Discover New Sales Opportunities Quickly

Find new projects, tenders, and opportunities in your target area with ease. Our powerful project search and filtering tools help you quickly find the opportunities that align with your current focus.

- Use advanced filtering to help you find the opportunities you want.

- Find companies involved and key personnel contact information.

- Secure new leads, build up sales pipeline and win more business.

Get Comprehensive Project Data at Your Fingertips

Easily access in-depth project profiles to gain key insights that help you make informed decisions faster. You'll save time digging for information and grow your business faster.

- Understand the background, scope, and key facts for every project.

- Track project timelines, CapEx, and budget details to align your strategy.

- Find the project owners, and other stakeholders involved in the project

- Stay informed with the most recent project updates and milestones.

Connect with the Right People

Boost your chances of securing more projects by easily tracking opportunities and connecting with the right companies and key decision-makers.

- Learn who the decision-makers are on any project and get phone number, email ID, LinkedIn URL to maximize your outreach efforts.

- Access to hard-to-find verified contact details, including phone numbers and email addresses.

- Connect directly with project owners, developers, GCs, and architects to build lasting relationships that fuel growth and success.

Increase Your Bid-Hit Ratio

Turn more bids into wins. Get the strategic intelligence you need to identify and secure the most profitable tender opportunities for your business.

- Shortlist the project tenders that align with your business goals.

- Make positive connections with key stakeholders.

- Prepare and submit a winning bid.Connect directly with project owners, developers, GCs, and architects to build lasting relationships that fuel growth and success.

- Expand your reach and grow your business.

Save Time & Money Resources

Save countless hours on manually finding new projects, tenders and project updates. Our dedicated team of over 100 researchers, combined with an AI powered intelligent opportunity-tracking system, handles the heavy lifting for you.

- Eliminate manual research with our AI-powered tracking.

- Free-up time and focus on closing more business.

- Reduce costs and risk by eliminating manual processes.

Additional Features & Benefits

Purpose-built features that solve real challenges and drive growth.

Customized Email Alerts

Stay informed with email alerts tailored to your preferences. Receive updates directly to your inbox that are most crucial to your business.

Integrated Sales Tools

Streamline sales efforts with tools designed for collaborative teamwork, including opportunity assignment and note-taking functionalities.

Multi-Language Support

Effortlessly translate the project profile into your preferred language, choosing from over 243 available languages.

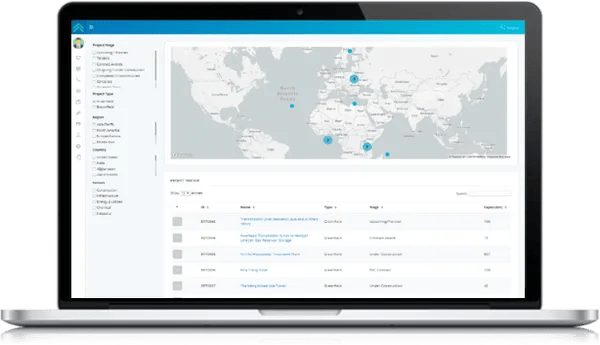

Interactive Dashboard Access

Get access to powerful and user-friendly web app that lets you search, filter, save, and share opportunities seamlessly from anywhere in the world.

Custom Download Option

Receive a customized CSV file of the projects, companies, and contacts that matter to you, available as a one-time download or on a recurring schedule.

Ease of Project Profile Sharing

Effortlessly share project profiles with your colleagues or other stakeholders through intuitive sharing options built into the platform.

24/5 - Priority Analyst Support

Get your queries prioritized and addressed swiftly by our dedicated analyst team within a 24- to 48-hour turnaround on data requests.

Export to Excel or CSV

Seamlessly export your dashboard data into Excel or CSV formats for in-depth analysis or presentation

Future Platform Updates

Benefit from continuous platform enhancements and new features designed to enhance your experience and utility.

Customizable Platform

Our team can customize your dashboard experience to align with your specific business requirements and workflows.

Personalized Training and Support

Receive tailored training sessions and dedicated support to ensure you maximize the utility of the dashboard, tailored to your unique business needs.

World-Class Data Security

Rest assured with top-notch security protocols keeping your sensitive data safe and secure at all times.

White Labeling

Personalize the platform with your logo and brand colors to showcase a consistent corporate image for your users and stakeholders.

Corporate Admin

Add, remove, and manage your organization's user accounts easily.

What people are saying about us

Frequently asked questions (FAQs)

Sign up to see more projects near you.