Table of Contents

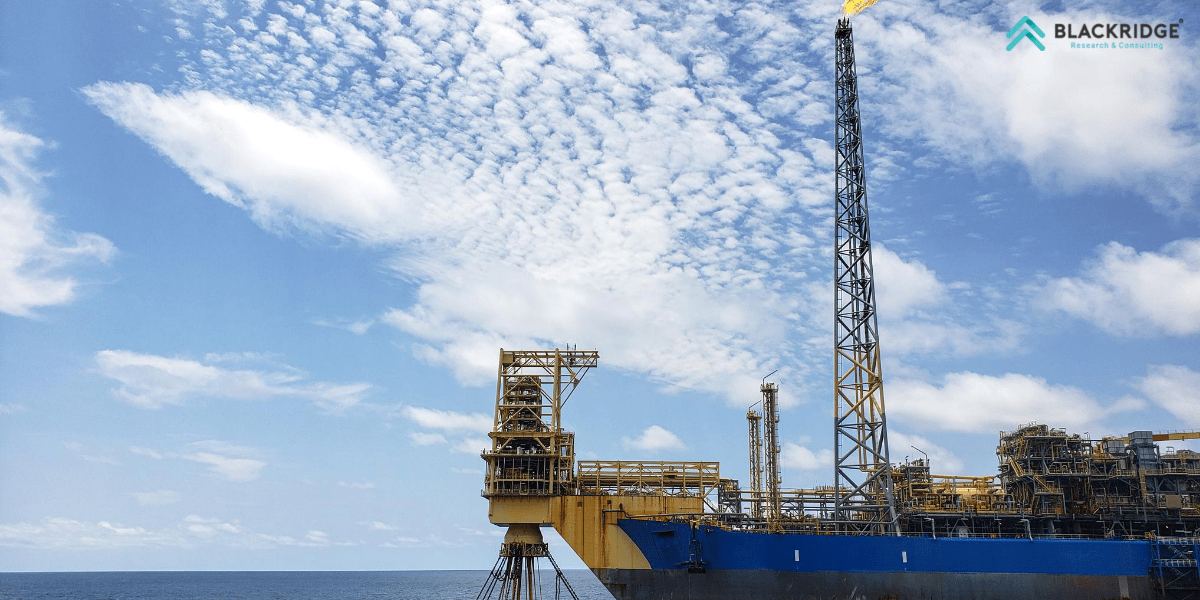

In the offshore oil and gas industry, FPSO means a Floating Production Storage and Offloading vessel. An FPSO is equipped with processing equipment that helps separate, store, and offload crude oil and gas extracted from subsea oil wells or platforms.

An FPSO is the most commonly used floating system for offshore projects. As a floating facility, an FPSO optimises offshore installation’s benefits and subsea wells’ potential. FPSOs are designed for reliable and safe performance, with strict adherence to industry compliance and environmental standards.

In this blog, we understand FPSOs, exploring their history, basic functionality, and structural components. Additionally, we'll discuss the different types of FPSOs and examine their respective advantages and disadvantages. We'll also highlight key projects and companies involved in this sector to provide a comprehensive understanding of the FPSO industry.

Curious to learn more about FPSOs? Let's dive in and explore further!

What is an FPSO?

FPSO (Floating, Production, Storage, and Offloading) is a floating vessel—an offshore production facility that contains processing equipment and storage for produced hydrocarbons. After processing oil and gas collected from sub sea oil wells, FPSO stores them safely before offloading them onto an oil tanker or transporting them through pipelines.

Typically, an FPSO looks like a ship-shaped vessel, with processing equipment above the vessel’s deck and hydrocarbon storage below the vessel’s deck (in the double hull). While a new-build FPSO is designed and constructed from scratch, a converted FPSO is made by modifying an existing vessel, such as a crude oil shuttle tanker.

Find FPSO Projects and Tender Leads around the GlobeClaim Your Free Leads!

A shuttle tanker is a ship that transports oil from offshore oil fields to onshore refineries. An offloading FPSO vessel makes it convenient to transfer crude oil to shuttle tankers for shipping to refineries instead of transporting oil via a pipeline to shore.

In recent years, FPSO conversion has involved building large FPSOs by converting very large crude carriers (VLCCs).

History of FPSO

The FPSO concept dates back to 1977 when Shell (the oil and gas major) built the world’s first FPSO platform “Shell Castellon” in Spain by converting an oil tanker. The FPSO performance has been steadily increasing over time. Before the advent of FPSOs, companies could only extract oil and gas from shallow fields and transport them via a subsea pipeline.

It was a challenging and economically unviable extraction method used in oil and gas fields far away from shore. However, FPSO deployments over the years have led to an increase in offshore oil gas production because of the cost-effective FPSO units, which are transferable and reusable at offshore sites.

FPSOs are widely used by oil and gas companies, which often lease FPSOs for the processing and storage of oil and gas. Around 270+ FPSOs are successfully operating worldwide. Contrary to traditional offshore oil and gas platforms, FPSOs are considered to be cost-effective, flexible, efficient, and safe.

What are the top countries using FPSOs? The list includes Brazil, the UK, Malaysia, Angola, Nigeria, Indonesia, Vietnam, India, Guyana, Côte d'Ivoire, and Ghana.

How Does an FPSO Work?

An FPSO receives hydrocarbons (crude oil, water, etc.) from a subsea reservoir through risers that separate these fluids in the topside production facilities.

Furthermore, an FPSO stores oil or gas before offloading to a shuttle tanker or conveying processed petroleum through flexible pipelines.

An offloading FPSO vessel is equipped with an offloading system to transfer crude oil to shuttle tankers for shipment to refineries.

The major components of an FPSO unit are:

Hull

The FPSO hull refers to the topside (above sea level). The hull is newly built or made by converting an existing tanker to project specifications.

Most hulls are supplied or built within the Asia Pacific region.

Topside

The topside of an FPSO refers to the upper portion of the vessel where most of the production processing equipment is located. This section typically includes facilities for crude oil processing, gas compression, water treatment, and other necessary operations.

The topside also houses living quarters for personnel, control rooms, and helidecks for crew transportation. Its design and layout are crucial for optimising production efficiency and ensuring the safety and well-being of onboard personnel.

Mooring System

The mooring system comprises anchors, connectors, and mooring lines. It holds the FPSO in place against waves and winds and supports a safe FPSO operation. The choice of an FPSO mooring system depends on the predominant environmental conditions and water depth.

The turret mooring system (TMS) consists of a fixed turret column held by an external or internal structure through a bearing arrangement. This system enables the vessel-bound components to weathervane freely around the fixed turret via several anchor lines connected to the seabed.

Contrary to a central mooring system that allows an FPSO to rotate freely, a spread mooring system fixes the FPSO from different locations. Disconnectable mooring systems are also used in environments prone to hurricanes or storms.

Risers

Risers are cylindrical conduits that primarily transfer fluids and gases from the subsea wellhead to the production platform or vessel.

Types of FPSOs

Based on their processing and storage capabilities, FPSOs are classified into four common types:

- Floating, Storage, and Offloading (FSO) unit

- Floating, Drilling, Production, Storage, and Offloading (FDPSO) unit

- Floating, Production, Storage, and Offloading (FPSO) unit

- Floating, Storage, and Regasification Unit (FSRU)

FSO: An FSO is an FPSO without oil or gas processing capability. Most FSOs are converted single-hull supertankers.

FDPSO: An FDPSO (Floating, Drilling, Production, Storage, and Offloading) unit takes the concept of an FPSO a step further by integrating drilling capabilities directly into the vessel. This creates a highly versatile offshore facility capable of handling the entire oil and gas production process, from exploration to offloading.

FPSO: A liquefied natural gas FPSO (LNG FPSO) provides a sustainable way to develop nearshore and offshore gas reserves.

FRSU: The floating storage and regasification unit (FSRU) operates similarly to land-based terminals. The purpose-built FSRU oil platform is equipped to distribute natural gas through specially engineered offshore and near-shore receiving facilities, as well as to vaporise LNG and transport it.

Advantages and Disadvantages of FPSOs

As the energy industry continues to evolve, it's crucial to assess the advantages and disadvantages of FPSOs to understand their role and impact effectively.

Advantages of FPSOs

Here are the primary advantages of FPSOs:

Adaptability and long service life: Adaptability to diverse environmental conditions and water depths, and sustainability in long-term (20 years or longer) operating conditions make FPSOs a preferred choice for many offshore oil- and gas-producing regions worldwide.

Freedom and flexibility: Oil and gas companies enjoy more freedom with FPSOs concerning exploration and extraction. As permanent structures and pipelines are not mandatory, an FPSO system also offers wide flexibility in operation and pipeline connectivity.

Better safety and storage: FPSO systems provide better safety and storage capacity than conventional processes and systems. Moreover, FPSOs maximise cost efficiencies during construction.

Read: FPSO vs. FSO: Understanding the Key Differences and Applications

Less expensive: FPSOs enable companies to produce oil and gas cost effectively than traditional offshore oil and gas production and storage.

Level-playing field: FPSOs ensure a competitive balance between smaller producers and larger producers. It is suitable for smaller oil fields The elimination of long-distance, expensive pipelines makes FPSOs particularly suitable for smaller oil fields.

Disadvantages of FPSOs

Let’s explore the major disadvantages of FPSOs:

Long construction and conversion time: FPSOs take around 1-2 years to build or convert and require a costly and timely environmental study for a specific field once accepted.

Tanker lightering: Lightering refers to “at-sea transfer” or “ship-to-ship transfer” of petroleum cargo from a large tanker to smaller ships or vessels. Sometimes, the transfer of crude oil from an FPSO to a shuttle tanker may pose oil spill risks and have disastrous consequences for the marine environment and local inhabitants.

Transport leaks: Compared to pipeline transport, FPSO vessel operations in deep water carry the highest crude oil spill risks from the transport function.

FPSO operators take utmost precautions to prevent oil spills. For example, FPSOs operating in the North Sea must abide by tough environmental regulations.

Key FPSO Projects and Companies

An FPSO project contributes to maintaining stable oil and natural gas supplies, as well as solving potential shortages, with significant crude oil and gas production capacities.

FPSO Projects

FPSO projects have demonstrated a strong comeback primarily due to the launch of new explorations stemming from depleting onshore oil and gas reserves, higher oil prices, creative financing options, and industry partnerships.

The fabrication and integration innovations at global shipyards and market dynamics are increasing the momentum of newly sanctioned projects. The rising energy demand is also leading to a surge in new FPSO projects in the Middle East, Latin America, South America, the United Kingdom, and West Africa, among other regions.

Key global FPSO contract awards for 2019-2022 include:

- Cameia, Angola

- Liuhua 11-1, China

- Limbayong, Malaysia

- Cambo, UK

- P-80, Brazil

- Maromba, Brazil

- Yellowtail, Guyana

- Dorado, Australia

- Gato do Mato, Brazil

- Marigold, UK

Let’s look at some well-known existing and upcoming FPSOs across the world:

FPSO Cidade de São Paulo MV23

The FPSO Cidade de São Paulo MV23 is stationed at the Sapinhoá field (formerly known as “Guara”), BM-S-9 Block in the “pre-salt” region of the Santos Basin (offshore Brazil).

FPSO Atlanta

The acquisition of FPSO Atlanta (formerly known as “OSX-2”) by the Brazilian oil company Enauta highlights a significant asset to be operated under ABS (American Bureau of Shipping) Class, with an estimated production capacity of 50,000 barrels of oil per day (BOPD) by this year.

The United States-based ABS is a leading ship classification organisation, which serves as a safety and risk management advisor to several industrial and government clients.

FPSO SEPETIBA

FPSO SEPETIBA is an offshore support vessel built in 2021 and deployed at the Mero field in the Santos Basin offshore Brazil.

FPSO SEPETIBA (formerly known as “Mero 2”) has a processing capacity of up to 180,000 BOPD and a minimum storage capacity of 1.4 million barrels of crude oil, among other features.

ONE GUYANA

ExxonMobil’s Yellowtail project in the huge Stabroek Block offshore Guyana will feature ONE GUYANA—SBM Offshore’s advanced FPSO, which is expected to begin production in 2025.

The FPSO includes standardised topside modules with an estimated optimum oil production capacity of 250,000 barrels per day (BPD). In addition, the vessel will have sizable storage and gas treatment capacities along with a water injection capacity of 300,000 BPD.

Hydrogen FPSO

South Korea-based Daewoo Shipbuilding & Marine Engineering Co., Ltd. (DSME) is working on a proposed FPSO that will leverage offshore wind power to produce hydrogen.

The floating hydrogen production offshore plant (Hydrogen FPSO) is considered an optimal solution to achieve energy independence and safely produce green hydrogen.

FPSO Companies

Leading FPSO companies can be categorised into two main groups: Engineering, Procurement, and Construction (EPC) contractors and Oil & Gas companies that operate FPSOs:

The leading FPSO owners include:

SBM Offshore N.V. (Netherlands): A Dutch multinational company specialising in FPSO services. SBM Offshore is a major contractor for designing, building, leasing, and operating FPSOs.

MODEC, Inc. (Mitsui Ocean Development & Engineering Company, Inc.) (Japan): A Japanese engineering and construction company specialising in offshore oil and gas facilities, including FPSOs.

BW Offshore Limited (Norway): A Norwegian company specialising in FPSO solutions, offering services across the FPSO lifecycle, from design and engineering to leasing and operation.

MISC Berhad (Malaysia): A Malaysian marine transportation and logistics company involved in FPSO ownership and operation.

Bumi Armada Berhad (Malaysia): A Malaysian multinational company providing offshore energy infrastructure and services, including FPSO operations.

Altera Infrastructure Holdings L.L.C. (Abu Dhabi): A company established by Abu Dhabi holding companies Mubadala and IHC to invest in and operate FPSOs.

Yinson Holdings Berhad (Malaysia): A Malaysian floating production services provider offering FPSO ownership, operation, and maintenance services.

Bluewater Energy Services B.V. (Netherlands): A Dutch company specialising in innovative floating production, storage, and offloading systems solutions.

Teekay Corporation (TK) (Canada): A Canadian marine transportation company with a fleet that includes FPSOs.

Saipem S.p.A. (Italy): An Italian multinational oilfield services company offering services across the FPSO lifecycle, from engineering, procurement, construction, and installation (EPCI).

You can check out the latest Top 20 FPSO Companies here.

Leading FPSO operators

FPSO operators play a critical role in ensuring the safe, efficient, and profitable production of oil and gas at sea. These companies are typically major integrated oil and gas companies or national oil companies with the expertise and resources to manage these complex offshore facilities.

Petrobras (Petróleo Brasileiro S.A.) (Brazil): The Brazilian national oil and gas company operates a fleet of FPSOs for domestic production.

ExxonMobil (USA): A leading integrated oil and gas company globally, ExxonMobil is directly involved in FPSO projects through its upstream operations (exploration and production).

Eni S.p.A. (Italy): An Italian multinational oil and gas company utilizes FPSOs for offshore oil and gas developments in its portfolio.

Petroliam Nasional Berhad (PETRONAS) (Malaysia): The Malaysian national oil and gas company, PETRONAS, operates FPSOs for projects in Malaysia and Southeast Asia.

Shell Plc (UK): A major integrated oil and gas company, Shell is a key player in FPSO projects around the world, acting as both an operator and partnering with EPC contractors.

ONGC (Oil and Natural Gas Corporation) (India): The Indian state-owned oil and gas company, ONGC, employs FPSOs for offshore oil and gas production in India.

Find FPSO Projects and Tender

Leads around the Globe Claim Your Free Leads!

Sinopec Group (China Petroleum & Chemical Corporation) (China): A major integrated oil and gas company, Sinopec is involved in FPSO projects in China and internationally.

Petrovietnam (Vietnam Oil and Gas Group or PVN) (Vietnam): The Vietnamese national oil and gas company, Petrovietnam, utilises FPSOs for offshore developments in Vietnam.

FPSO Specialists:

BW Energy (Norway): Similar to BW Offshore, this company focuses on FPSO solutions, potentially specialising in smaller or less complex FPSO projects.

Chevron Corporation (Chevron) (USA): A major integrated oil and gas company, Chevron utilises FPSOs for offshore production projects around the world and collaborates with EPC contractors for FPSO development.

Other key players operating in the global FPSO market are Keppel Offshore & Marine (Keppel O&M) and Hyundai Heavy Industries Co., Ltd. (HHI).

Emerging technologies and advancements in FPSOs

The future of FPSO vessels is getting better with new technologies like digitalization, automation, and sustainability. Remote Operations Centers (ROCs) are revolutionising operations by facilitating real-time data transmission, while digital twins are enhancing maintenance scheduling optimization.

Also, Advanced analytics play a crucial role in predicting equipment failures, thereby preventing costly downtime.

Lighter hull materials and 3D printing make FPSOs more fuel-efficient. Sustainability technology like carbon capture reduces pollution, and using renewable energy and water treatment systems helps to minimise wastewater discharge.

Cybersecurity measures are of utmost importance to safeguard against cyberattacks. The integration of autonomous subsea vehicles (ASVs) for subsea well inspections and maintenance is enhancing safety and efficiency in offshore operations.

Blackridge Research & Consulting – Global Floating Production Storage and Offloading (FPSO) Market Report

If you are looking for a detailed global FPSO market analysis, check out Blackridge Research & Consulting’s Global Floating Production Storage and Offloading (FPSO) Market Report .

The report provides deep insights into the current global and regional market demand scenario and various factors affecting the FPSO market growth.

The regional market analysis covers the FPSO market across regions, including Asia-Pacific, Africa, Europe, the Middle East, and North America.

The major demand drivers of the FPSO market include:

- Continued capital spending on deepwater exploration

- Depleting onshore oil and gas reserves

- New deepwater asset discovery

- A rise in crude oil prices

- Short development schedules

The FPSO market segmentation and forecast are based on the following:

Construction

- New Build

- Converted Hull

Read: Top FPSO Companies in India

Depth

- Shallow Water

- Deep Water

- Ultra-Deep Water

Hull Type

- Single Hull

- Double Hull

Propulsion

- Self-Propelled

- Towed

In addition, the report assesses the FPSO market size, competitive landscape, market opportunities, and threats.

Would you like to explore new project opportunities in the oil and gas industry? Explore the Global Project Tracker for in-depth coverage of key upcoming/future projects in the oilfield services sector.

Conclusion

FPSOs are vital assets in offshore oil and gas extraction, offering versatility, cost-effectiveness, and safety. They come in various types, each tailored to specific offshore needs, offering adaptability and flexibility. They have a rich history dating back to the late 1970s, evolving to meet industry standards and regulations. Despite challenges like construction times and transport risks, they significantly contribute to industry growth.

With a global resurgence in FPSO projects, key regions include the Middle East, Latin America, and West Africa. Major companies like SBM Offshore and Petrobras, along with operators like ExxonMobil and Shell, lead in FPSO development, ensuring safe and efficient production. FPSOs remain pivotal in offshore oil and gas production, contributing significantly to the industry's sustainability.

Looking for more than generic information on FPSO vessels around the Globe?

Subscribe to our Global FPSO & FSO (Oil & Gas) Projects and Tender Database to access reliable and high-quality insights on upcoming, in-progress, and completed floating offshore plant projects across the world or in your desired location.

Our user-friendly platform provides essential details, timely updates, key stakeholder contact information, and business opportunities tailored for engineering companies, industry professionals, investors, and government agencies.

Start a free demo to take your business to the next level!

Leave a Comment

We love hearing from our readers and value your feedback. If you have any questions or comments about our content, feel free to leave a comment below.

We read every comment and do our best to respond to them all.