Table of Contents

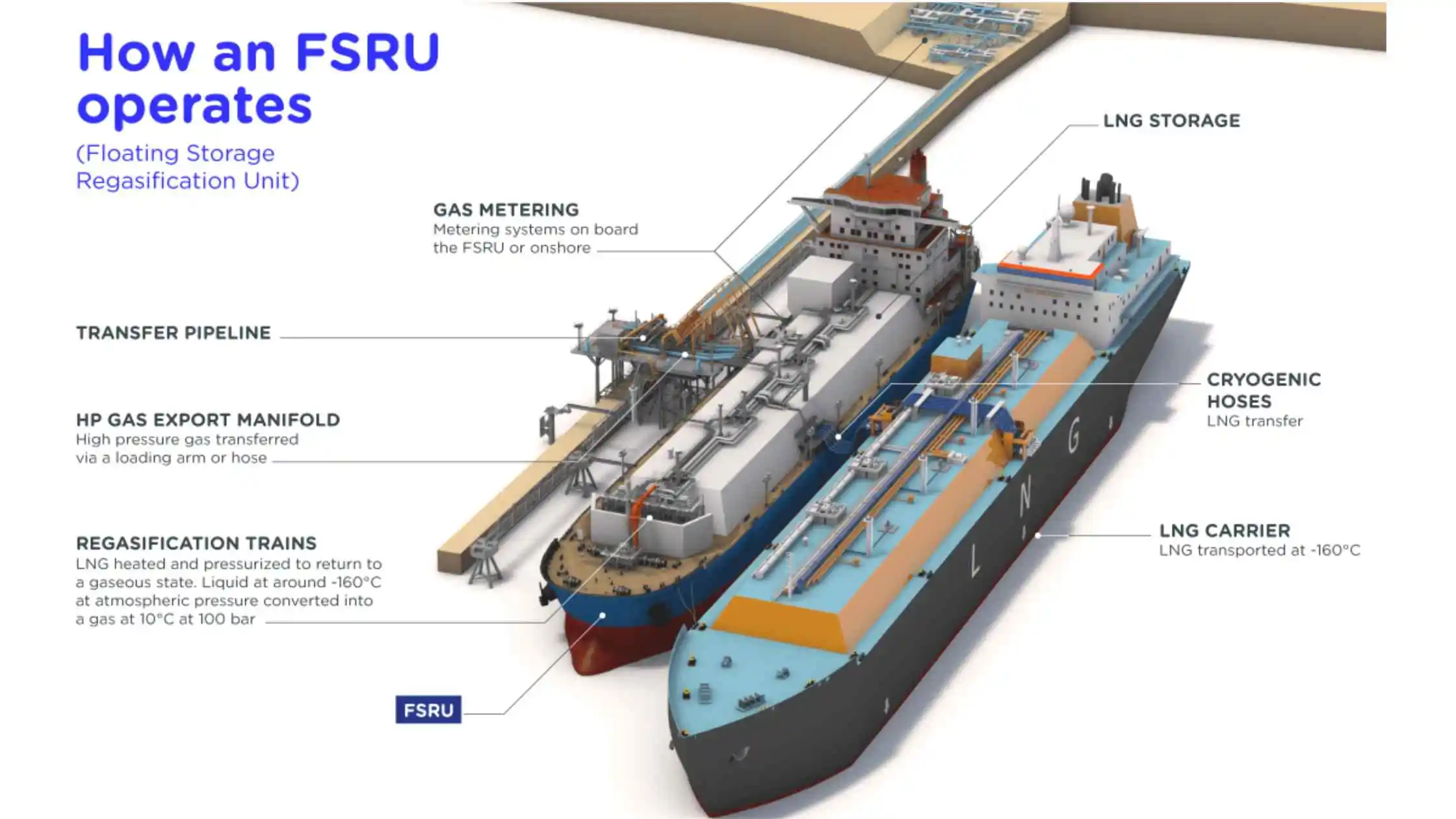

Floating Storage and Regasification Unit (FSRU) is a specialized floating vessel used in the LNG (Liquified Natural Gas) industry to store and regasify LNG. FSRU function as mobile gas terminals, storing regasified LNG before offloading it to shore for distribution. Floating ships including FSRU, FLNG, and FPSO offer versatile options for gas extraction, storage, and transportation.

FSRU is used to regasify the LNG which is cooled in extremely low temperatures of -160 degrees Celsius for transportation. This process can be performed directly from conventional LNG ships into insulated tanks onboard the FSRU.

FSRU is usually stationed offshore to enhance accessibility and flexibility in global LNG supply chains, particularly in areas with limited infrastructure. The structure of FSRUs is flexible to meet the offshore demands like the structure of the port and the transfer of LNG by LNG Carriers.

Here we understand the meaning of FSRU, the working principle, and how it is better than onshore LNG terminals.

What is an FSRU?

FSRUs are self-propelled Moss-type, conventional, or large LNG tankers retrofitted with auxiliary equipment and regasification systems. LNG is transported at a semi-cooled temperature of -160 degrees Celsius, and needs to be heated to return to its original gaseous state before it can be stored or distributed. This process is both costly and time-consuming. A floating storage unit equipped with a reliquefaction plant saves time and reduces the expenses associated with this process.

Some FSRUs are designed without self-propulsion and feature customized storage and regasification systems to meet specific customer requirements. Various FSRU designs are available considering the local market needs, existing infrastructure, required volumes, and budget priorities of the customers. These options showcase the flexibility and diversity within the FSRU industry.

Find FSRU Projects and Tender Leads Around the Globe Collect Your Free Leads Here!

In contrast, FLNGs act as self-contained processing plants, liquefying natural gas from offshore sources for transport via LNG carriers. FPSOs are designed for crude oil extraction, store and offload oil from reservoirs. There are over 50 FSRU operational units worldwide and ongoing construction reflecting the rising demand for flexible LNG solutions.

How Does an FSRU Work?

Image Credit: totalenergies.com

FSRU is based on the working principle of regasification. Regasification is the conversion of liquefied natural gas (LNG) back into its gaseous form at high pressure. FSRU which is docked offshore consists of a regasification unit that converts the natural gas carried by the LNG carrier. The gas in liquid form is pressurized and vaporized to distribute to an onshore pipeline.

The LNG carriers feed the gas into FSRU at a pressure of roughly 5.5 bar(g) and a temperature of -160°C. But the output is fixed at a rate of about 50 ~ 1,000 mmscfd at a pressure range of 90 ~ 103 bar and a temperature of 5°C.

There are vaporizer trains in the regasification facility. These regasification trains in the forship area work with glycol water loops and seawater systems. The heat for vaporizing the LNG is provided by four seawater pumps in these vaporizer trains. Sea water is not directly used as a medium for heating because of safety issues.

The initial stage of regasification starts with the supply of LNG via the submerged cargo tank pumps to a suction drum located on the trunk deck. The gas enters the regasification train which consists of an LNG booster pump, LNG vaporizer, and LNG heater. The gas from the regas feed pump is directed to the booster pump suction pots where the pressure is increased.

Next, the LNG passes through a high-pressure gas vaporizer which evaporates the LNG using the glycol water via a seawater heating medium. The pressure of natural gas is reduced here. LNG is heated to convert it minus 30 degrees Celsius from -160 degrees. The gas then flows to the gas heater and uses the glycol water as a heating medium to raise the temperature of the NG.

Finally, the gas is exported at a temperature above 5 degrees Celsius. The natural gas from the Regas train is exported to the onshore pipeline after regulating the pressure by the back pressure control valves.

Benefits of FSRU

FSRU offers various solutions in the oil and gas industry. Some of them are:

- Reduced upfront investment

- Reduced operating cost

- Increased flexibility

- The CAPEX of FSRU is low compared to a land-based regasification unit

- Chartered FSRU units are cost saving

Let’s explore in detail:

Reduced construction time

Onshore terminals take four to five years to complete and start functioning. Unlike this, FSRUs need less time to be commissioned, around one to two years. Wondering why? When regasification units are moved offshore the construction time of complex structures is reduced significantly.

Here we can explain it with the “FSRU Independence” built by Hyundai heavy industries in South Korea. It started construction in 2012 and gas supply in 2014. Within two years, Independence was able to supply all the natural gas required by Lithuania.

Read: FPSO vs. FSO: Understanding the Key Differences and Applications

Onshore LNG terminals like the South Hook LNG terminal located near Milford Haven, United Kingdom, began construction in 2004 yet did not get commissioned until 2009. This underlines the construction time taken to complete an onshore LNG terminal which includes regasification units and pipelines.

Lower Investment

For investors eyeing long-term returns in compliance with global energy demands, FSRU is a great option. The comparison of the cost difference between an onshore LNG terminal and an FSRU vessel gives you a better understanding. With several construction and upfront investments the onshore plant costs around USD 1 billion. The price of an FSRU comes to around USD 330 million. Further, the cost of an FPSO is reduced with the remodification of existing LNG carriers.

Flexibility

The flexibility of FSRUs is helpful in many ways. First, it can be relocated according to the needs and restructured according to the port. Second, it can fulfill the needs of the market by serving other possibilities like acting as an FSU (Floating Storage Unit) or LNG vessel. The early gas option and reuse according to the requirement makes it a more attractive option than onshore LNG constructions.

Top FSRU companies in the World

In July 2024, Deutsche ReGas and Norway's Hoegh LNG have agreed to develop the world's first floating import terminal for hydrogen. Here are some of the global top FSRU companies :

| Company Name | Country of Origin |

| HÖEGH LNG AS | Norway |

| Excelerate Energy, Inc. | United States |

| New Fortress Energy Inc. | United States |

| BW LNG | Singapore |

| Mitsui O.S.K. Lines, Ltd. (MOL) | Japan |

| Bumi Armada Berhad | Malaysia |

| Flex LNG | Greece |

| Gazprom | Russia |

| Eagle LNG | Netherlands |

| Dynagas LTD | Greece |

| Exmar NV | Belgium |

The Future of FSRUs

The demand to reduce carbon footprint and abundant LNG supply has made the FSRU market more stable. To meet these demands FSRUs can be a stable solution. The number of FSRUs is increasing steadily with the addition of 48 ships in the fleet according to 2022 data. The total number of FSRU vessels has reached 734 in the same year including LNG tankers.

Another prediction is the FSRU market depends on the LNG market growth. While understanding the global gross LNG trade with 542.4 billion cubic meters in 2022, which is 5.8% higher than the LNG trade in 2021. The LNG trade is anticipated to expand in the future due to Asia's and Europe's growing need for natural gas.

Looking for FSRU Market Outlook to 2029? Collect Your Free Leads Here!

LNG consumption worldwide has increased at a rate of 2.8% from 2022 to 2023. This growth is a positive sign in the requirement for new additions like increased storage and regasification capacity. LNG market outlook to 2029 predicts LNG market volume will be doubled driven by clean energy, decarbonization, and energy security. Also, the IMO revised greenhouse gas strategy focuses on net-zero emissions by 2050. All these points on clean energy and growth in the LNG market which reflects a positive impact in FSRUs.

Conclusion

FSRUs are storage and regasification units that play a crucial role in the LNG industry. It offers benefits like reduced upfront investment, operating costs, increased flexibility, and quicker construction time compared to onshore terminals. The future of FSRUs looks promising due to the increasing demand for clean energy, abundant LNG supply, and the growth of the LNG market.

FAQS

What is FSRU and how is it different from FPSO?

FSRU is a vessel used for LNG storage and regasification, while FPSO handles oil and gas production, storage, and offloading.

What is the difference between FSRU and LNG carrier?

Difference between an FSRU and LNG carrier is, FSRUs stores, regasifies and transport LNG while LNG carriers only transport it.

What is the largest FSRU in the world?

FSRU Bauhinia Spirit is the world's largest floating storage and regasification unit (FSRU) with a storage capacity of 263,000 m3.

Connect with decision-makers of floating offshore wind projects around the Globe for business opportunities.

Subscribe to our Global FSRU Project and Tender Database to get access to reliable and high-quality insights on upcoming, in-progress, and completed floating offshore plant projects across the world or in your desired geographical location.

Our user-friendly platform provides essential details, timely updates, key stakeholder contact information, and business opportunities tailored for engineering companies, industry professionals, investors, and government agencies.

Start a free demo to take your business to the next level!

Leave a Comment

We love hearing from our readers and value your feedback. If you have any questions or comments about our content, feel free to leave a comment below.

We read every comment and do our best to respond to them all.